July 24, 2023

ADDDAM selects Additive Industries’ 3D metal printer MetalFABG2 for expansion in the automotive and machine engineering industry

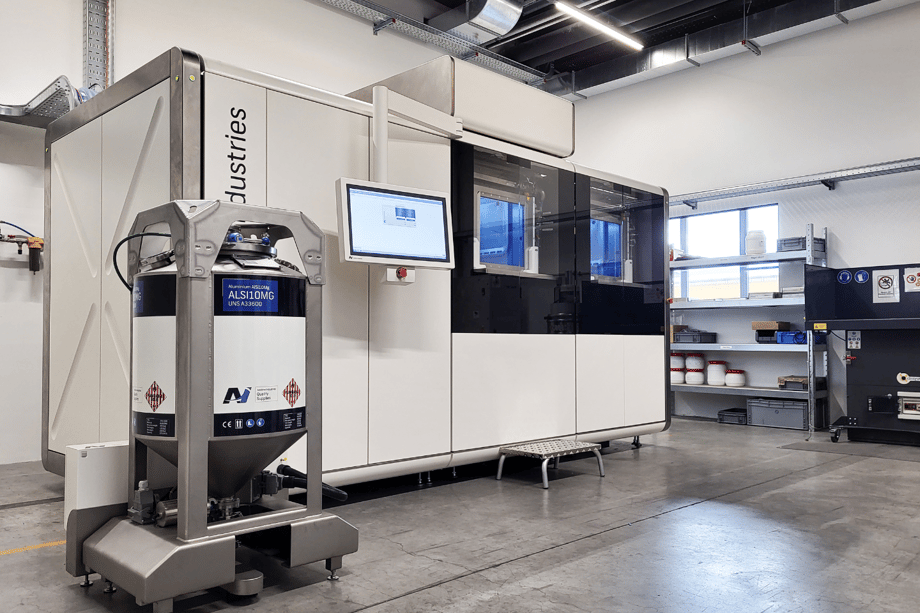

Eindhoven, The Netherlands, 24 July 2023 – 3D metal printer manufacturer Additive Industries installed its MetalFABG2 3D metal printer at ADDDAM, a volume...