Consultancy services for MetalFab customers

New to AM or an experienced user, our team can help maximise the benefit that AM can bring to your business

We understand, advise, optimise & productionise your AM applications

A specialist team of design, manufacturing & materials Engineers with 100+ year's experience developing AM products across Aerospace, Motorsport, Energy, Automotive & Hi-Tech Industries.

Watch the film to find out more:

Supporting customers throughout their journey to adopt, develop and maximise the benefits of metal additive manufacturing - from the early stages of adoption through to the development of advanced applications and materials. Collaboration with Additive Studios will help you:

Navigate the complex AM journey

![]()

Reduce development timeline

![]()

Reduce overall AM production costs

![]()

Fast track knowledge in your organisation

![]()

The Additive Studios customer journey enables

> Accelerated AM experience & knowledge

> Accelerated customer application maturity

Accelerate Adoption of Metal AM

- What should I build & how?

- Part assessments / business cases / DfAM workshops

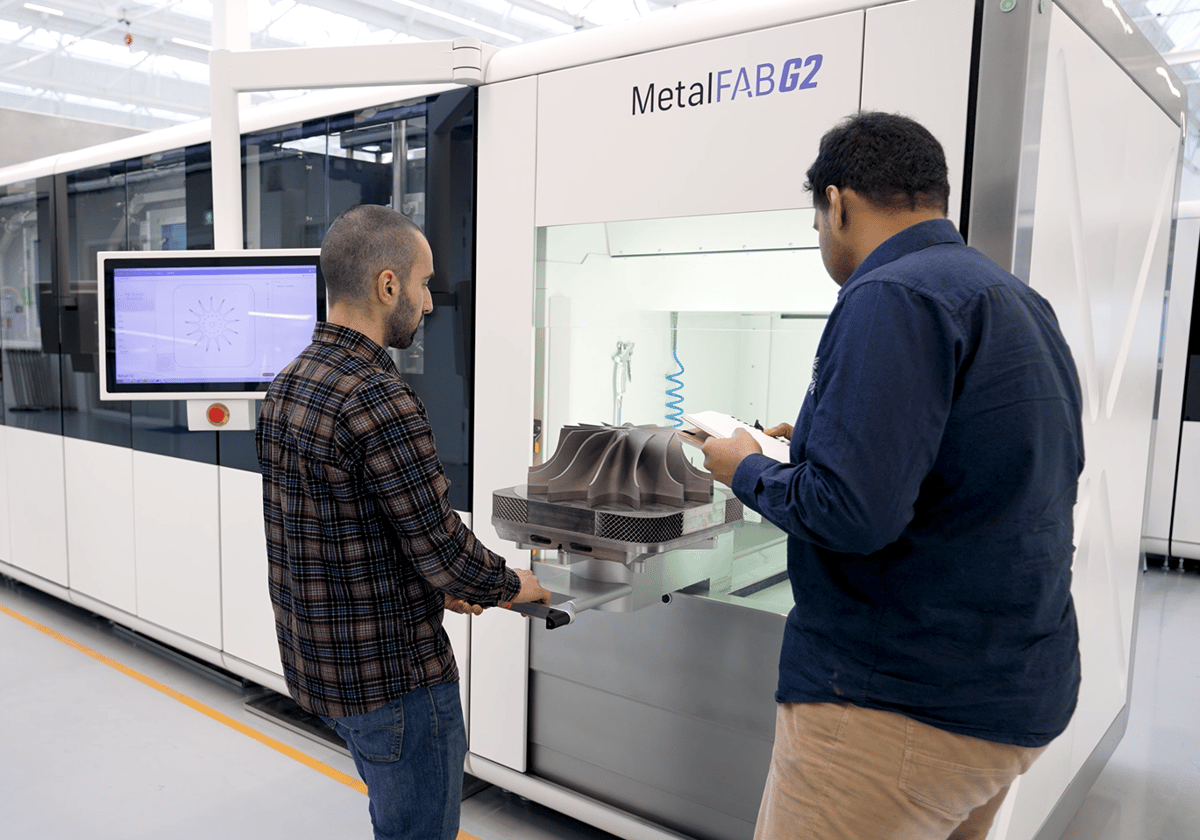

- Proof of concept & early series production of parts

- R&D stage material exploration

Equipping Customers for AM Production

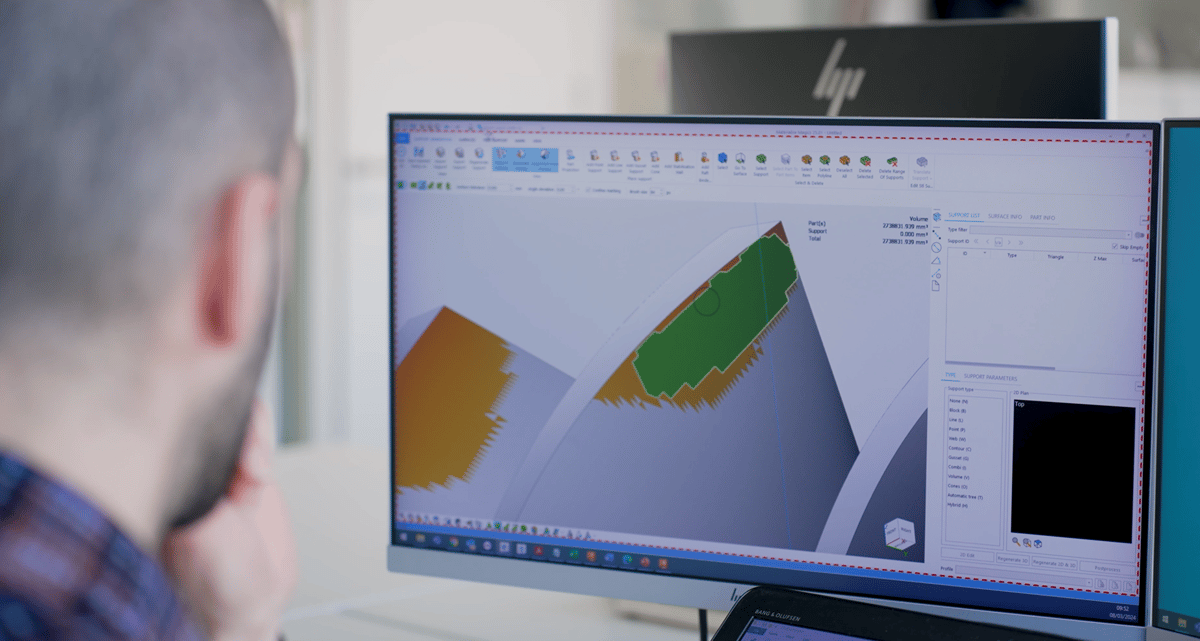

- Detailed application development

- Detailed design for manufacture & production geometry freeze using advanced industry techniques & toolsets

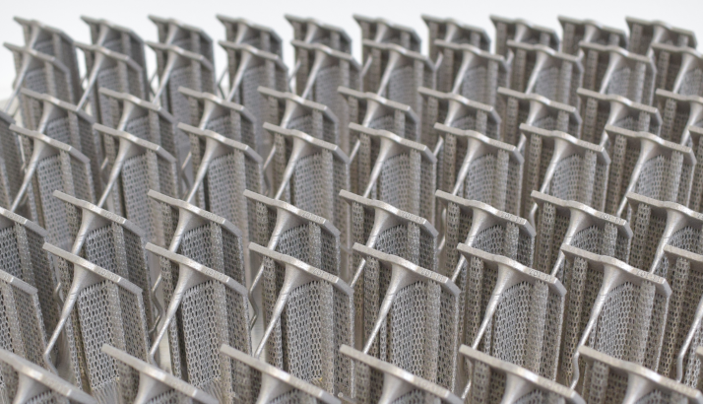

- Bespoke customer parameter & material development

Additive Studios Training Courses

- Phase 1 Modules: Early stage DfAM knowledge & principles of AM value add applications

- Phase 2 Modules: Building Parts on the MetalFab – Process & Application knowledge transfer for beginner & advanced users

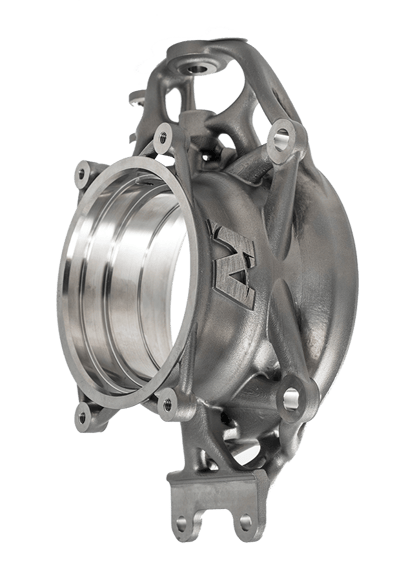

Our capabilities

We can provide a range of services for AM users at any stage of their journey, including:

- AM design assessment, consultation & support

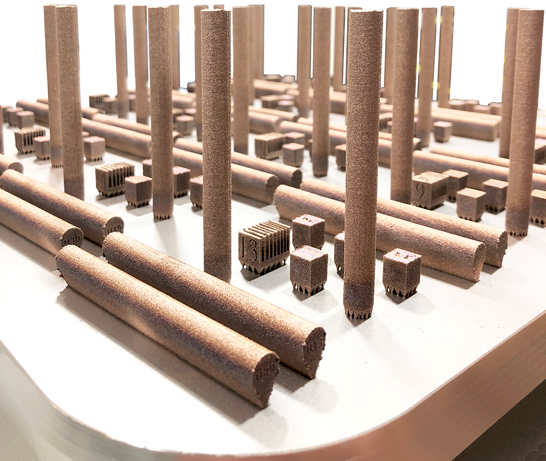

- AM demonstration part manufacturing and early series production

- Bespoke application development projects

- Process development and parameter optimisation for specific applications

- New material development

We work alongside our customers throughout their journey from machine purchase to serial production

“We have found a partner in Additive Industries that not only knows what is required to employ 3D metal printing in an industrial context but also shares our passion for digital technology in order to continuously improve the service we provide to our clients.”

Egon Seegers

General Manager service parts, ABB

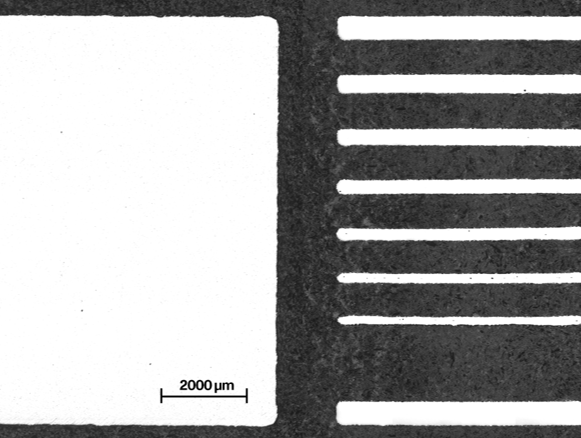

We support our customers to optimise and develop AM process parameters to meet very specific application requirements

This approach can help to increase productivity to reduce part cost/increase throughput, produce thin wall structures with structural requirements or optimise process/parts for specific engineering requirements, i.e. high cycle fatigue.

We can guide our customers throughout the entire journey to develop a new material

Real-life success stories from the field

Our Additive Studios Team has benefitted a range of customers by reducing costs, speeding up production with automation, and increasing product quality and design flexibility.

Find out how we worked with Volkswagen Group to realise significant cost and lead time reductions with a volume tooling application for their Tiguan vehicle production line....

Support packages, ready made solutions and standard training courses

We offer a range of standard training packages and support solutions covering everything from exploring the basics of metal AM with MetalFab through to advanced parameter development and build strategies.

AM Exploration

Application Specific Parameter Development

New Material Feasibility

R&D Material Development

Foundation Material Development

Design for AM

AM Production

Reach out to us!

Our specialists are eager to dive into your AM challenge

We will get back to you within 48 hours