Our MetalFab Portfolio

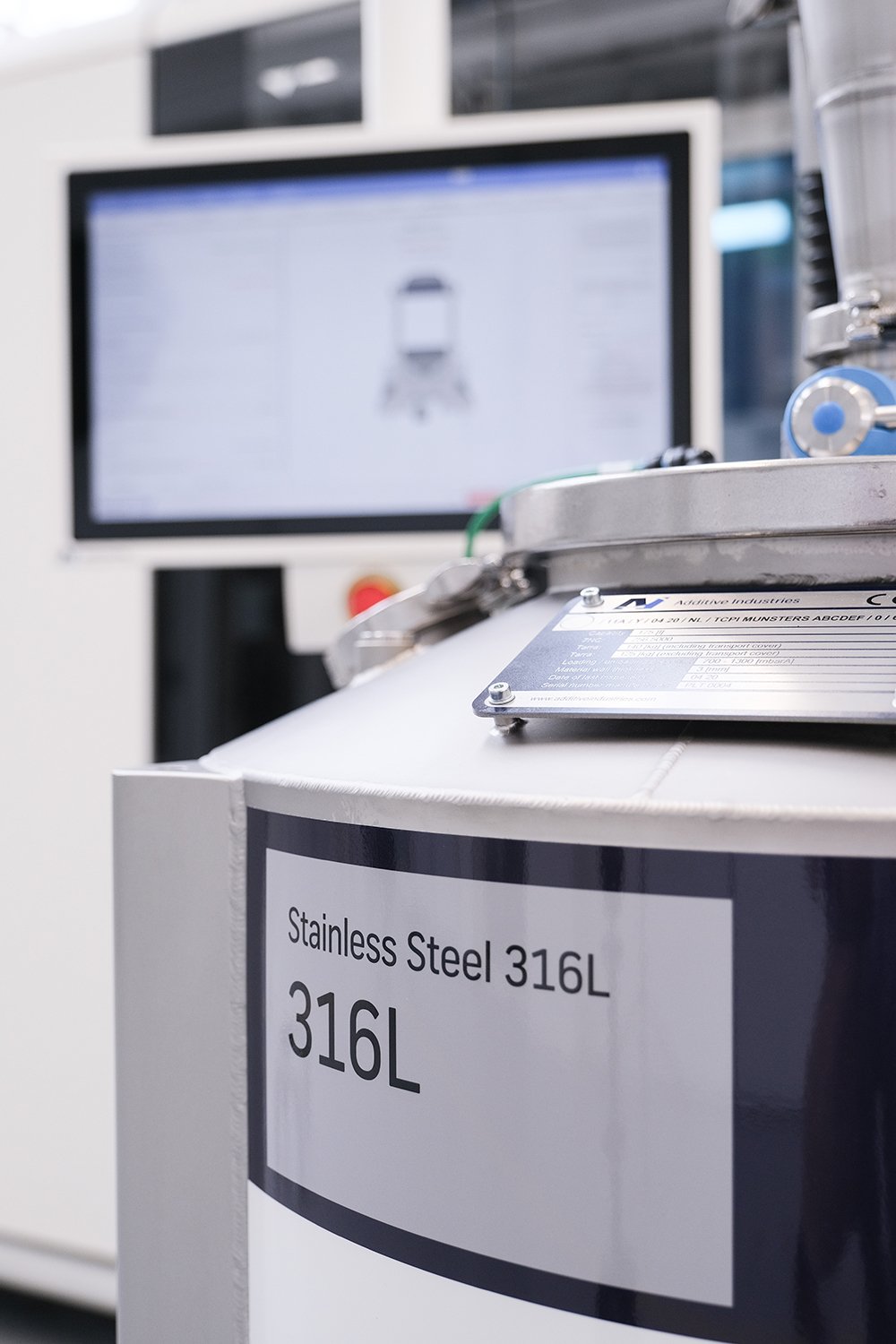

Powder

Load

Tool (PLT)

We recognise the critical nature of the metal powder in our systems from a quality and safety perspective, which is why the MetalFab is designed to minimise the exposure of powder particles to oxygen, moisture and human contact.

The Powder Load Tool (PLT) can be filled with metal powder directly at the atomization source under inert conditions and transported to site to be loaded into the MetalFab system.

The PLT ensures that powder not in the MetalFab is constantly kept under inert conditions and can be loaded to the system at any point it is needed, including while the system is printing.

PLT Supply Process Flow

Working with our approved powder supply partners the PLT process chain allows MetalFab customers to improve their quality control, health and safety and factory workflow.

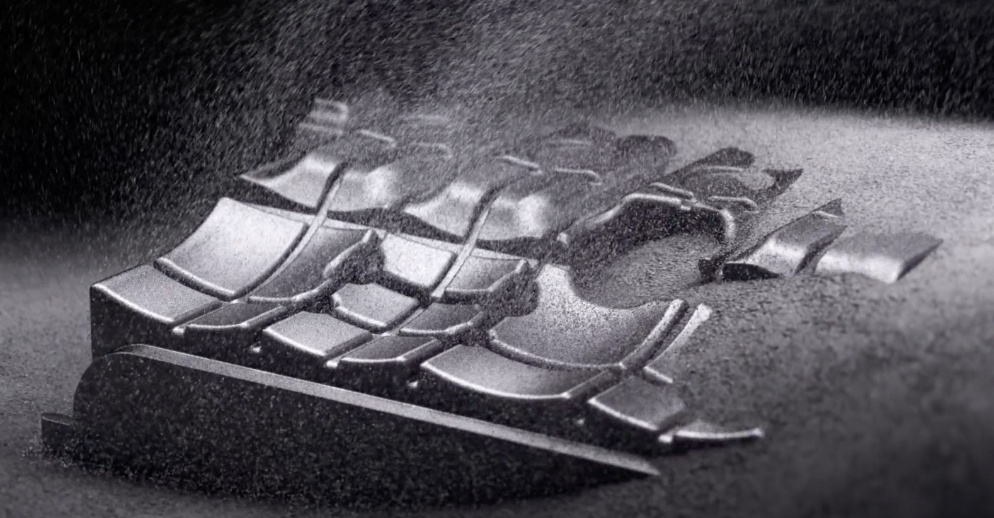

Explore our Powder Material Range

Our MetalFab systems process a wide range of metal materials which can be managed with the PLT factory workflow solution.