Metal Additive Manufacturing Market

Metal 3D Printing: The Market for High-Value Metal Parts

Expenditure on high-value metal parts reached €115B in 2021, with Metal Additive Manufacturing accounting for a fraction of it. Those falling under this category have high-performance requirements, complex geometries, as well as the need for great structural integrity. The vast majority of these components are made using conventional manufacturing technologies such as casting, forging, machining/milling, and metal injection molding.

Metal 3D Printing Is Expected To Grow Its Share Of The Industrial Parts Market

Metal AM has a significant potential to replace existing conventional methods of metal parts production. It's being increasingly adopted as the manufacturing method of choice in key end markets as printed parts become more economical. Such expansion is primarily driven by a substantial increase in first-time adoption of AM, as well as a shift in existing customer usage due to the qualification of additional applications and expanded operations.

Casting

process of pouring molten metal into a mold to achieve desired shape after cooling

Typical use cases

Cost effective process at scale with relatively high degree of variability (depending on cooling time, process and mold quality). Mostly used in automotive, construction and defence sectors

Substitutability with metal AM

Medium to high substitutability depending on part complexity, size and material

Machining and Milling

Cutting excess parts from a solid metal piece to achieve desired shape and geometry

Typical use cases

Relatively expensive vs. casting and forging with higher level of accuracy. Primarily utilised by aviation, space, electronics and medical industry

Substitutability with metal AM

Strong substitutability with most parts being high accuracy/ complexity

Forging

Forming/ shaping metal parts through hammering, pressing or rolling heated metal ingots

Typical use cases

Cost effective process at scale with relatively high degree of variability (depending on process efficiency). Mostly used in construction and general industry (tooling, jigs, etc.)

Substitutability with metal AM

Medium substitutability given most parts are relatively low complexity

Replacing conventional manufacturing technologies

Which industries are utilizing metal additive manufacturing?

Metal AM adopters are motivated by a desire to embrace complexity in their part designs in order to maximize functional performance and obtain a competitive advantage in their respective sectors. Most notably, the aerospace, automotive, high-tech, and energy industries are making waves in their efforts to shift from traditional manufacturing to metal 3D printing.

Metal 3D printing for Aerospace

Increased component quality and performance is the primary driver of metal AM in aviation. Industry experts agree that weight reduction and increased turbine or hydraulic performance have a massive impact on performance. Once initial qualification efforts are concluded, metal AM can add value through significant cost reductions.

"With the integration of a MetalFAB AM printer at Safran, we want to meet the challenge of performing at the appropriate level of raw material quality and productivity for aluminum"

FX Foubert

CEO of Safran additive manufacturing campus

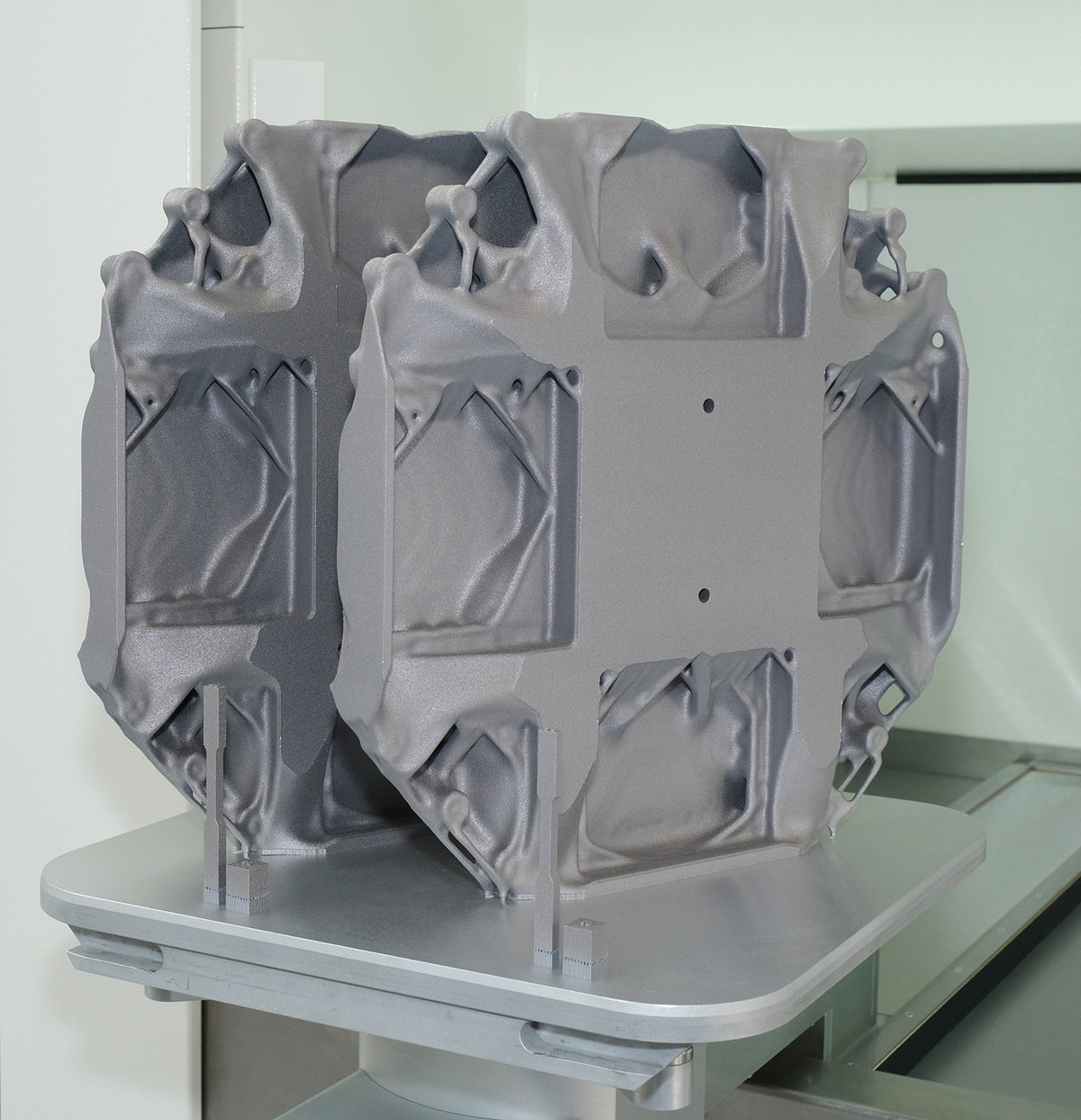

Metal 3D Printing for Automotive Parts

Metal AM is propelling growth within the automotive industry by increasing value through shorter time to market and applications in high-performance segments. The key driver of metal AM adoption in automotive is cost reduction, with car manufacturers continuing to seek high automation from metal AM systems with reproducible and predictable part qualities.

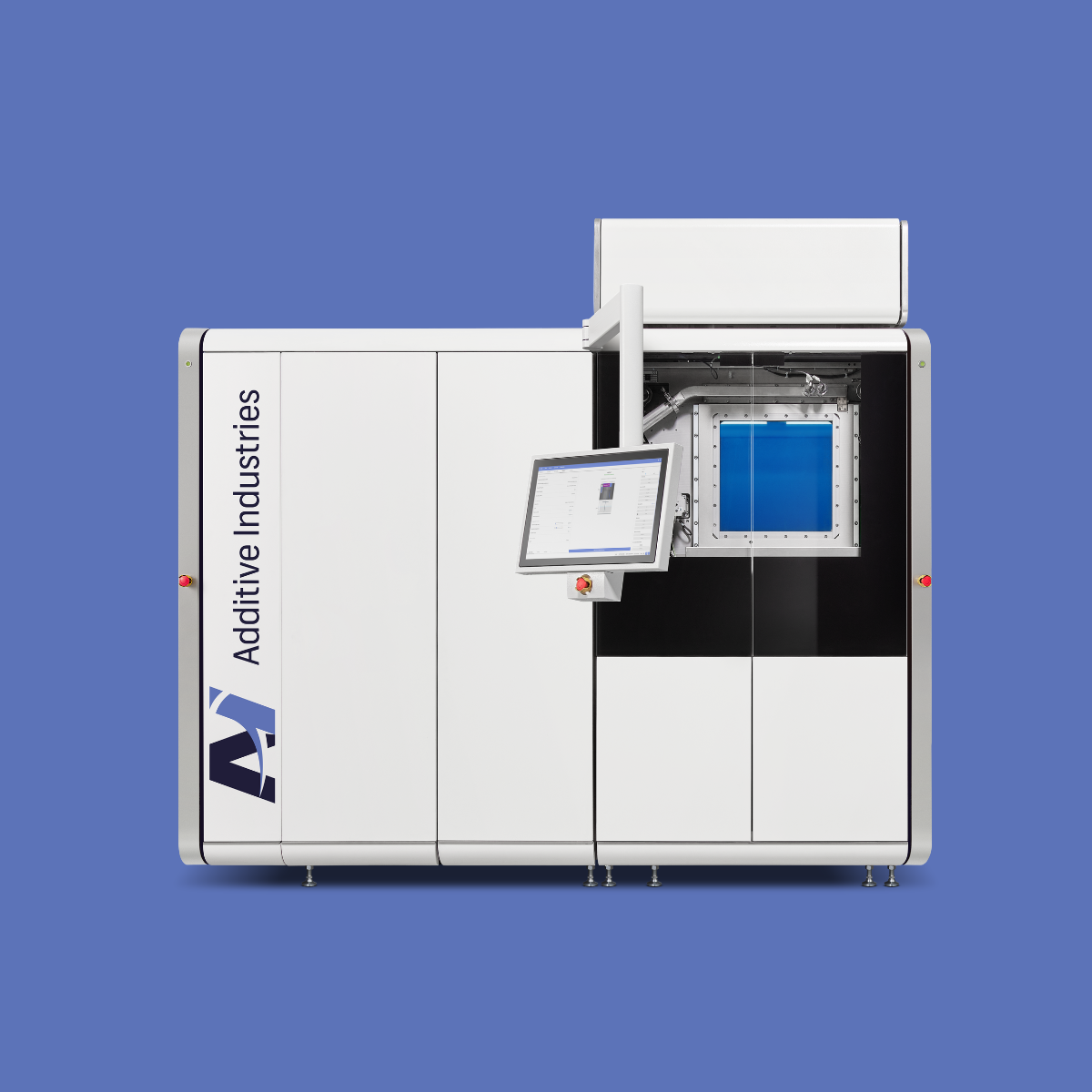

VW achieved a 650% cost reduction by manufacturing their Tiguan production tooling on the Additive Industries MetalFAB system, as well as a considerable decrease in lead time and the ability to swiftly iterate designs with improved performance.

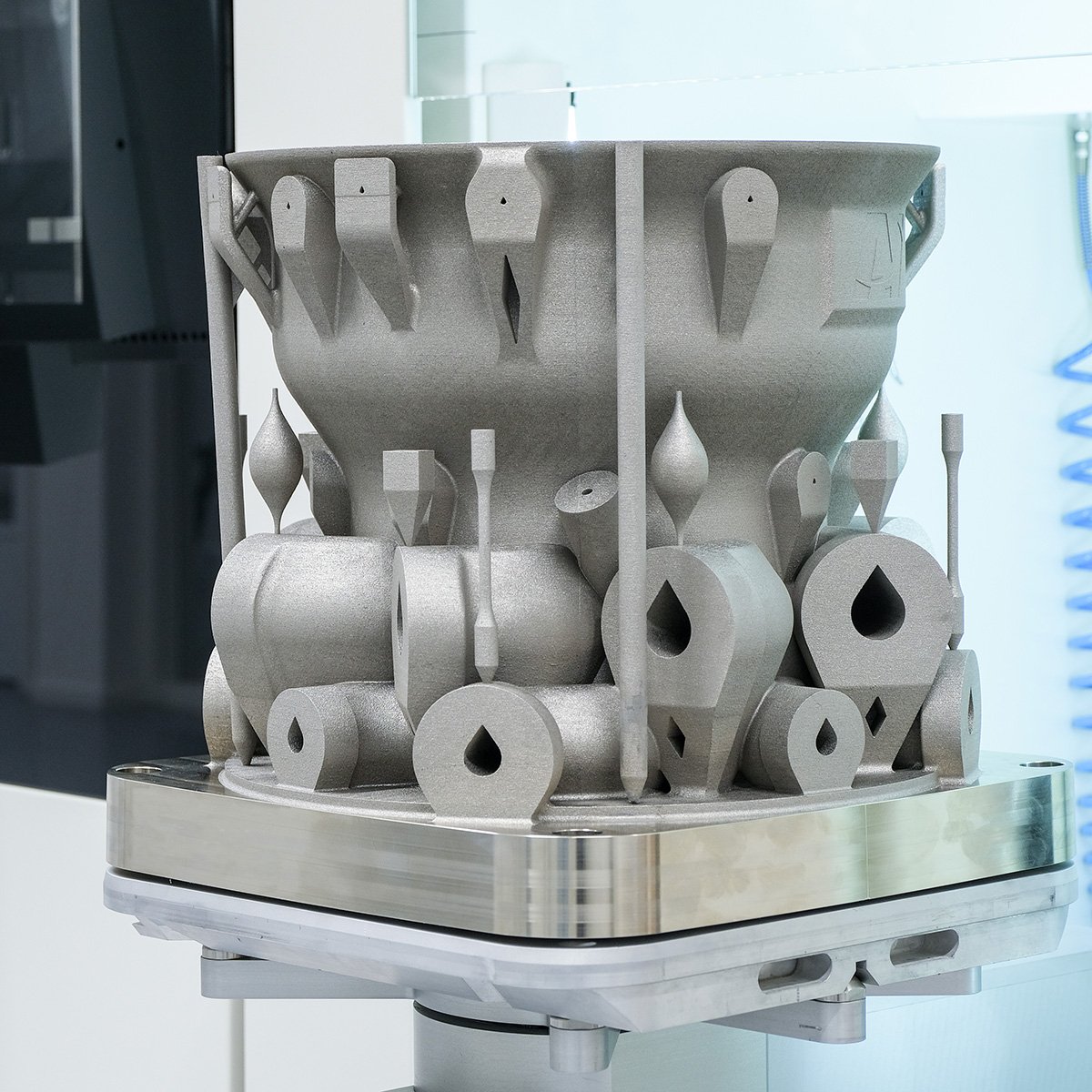

Metal 3D Printing for High-Tech Parts

Metal AM's ability to handle refractory and other exotic materials that are expensive to process traditionally bolsters growth in the High Tech industry. When used in 3D metal additive manufacturing, these alloys provide substantially more functionality than their traditional counterparts. These industries are particularly interested in metal AM because of its potential to reduce lead times, optimize part quality, and maximize accuracy.

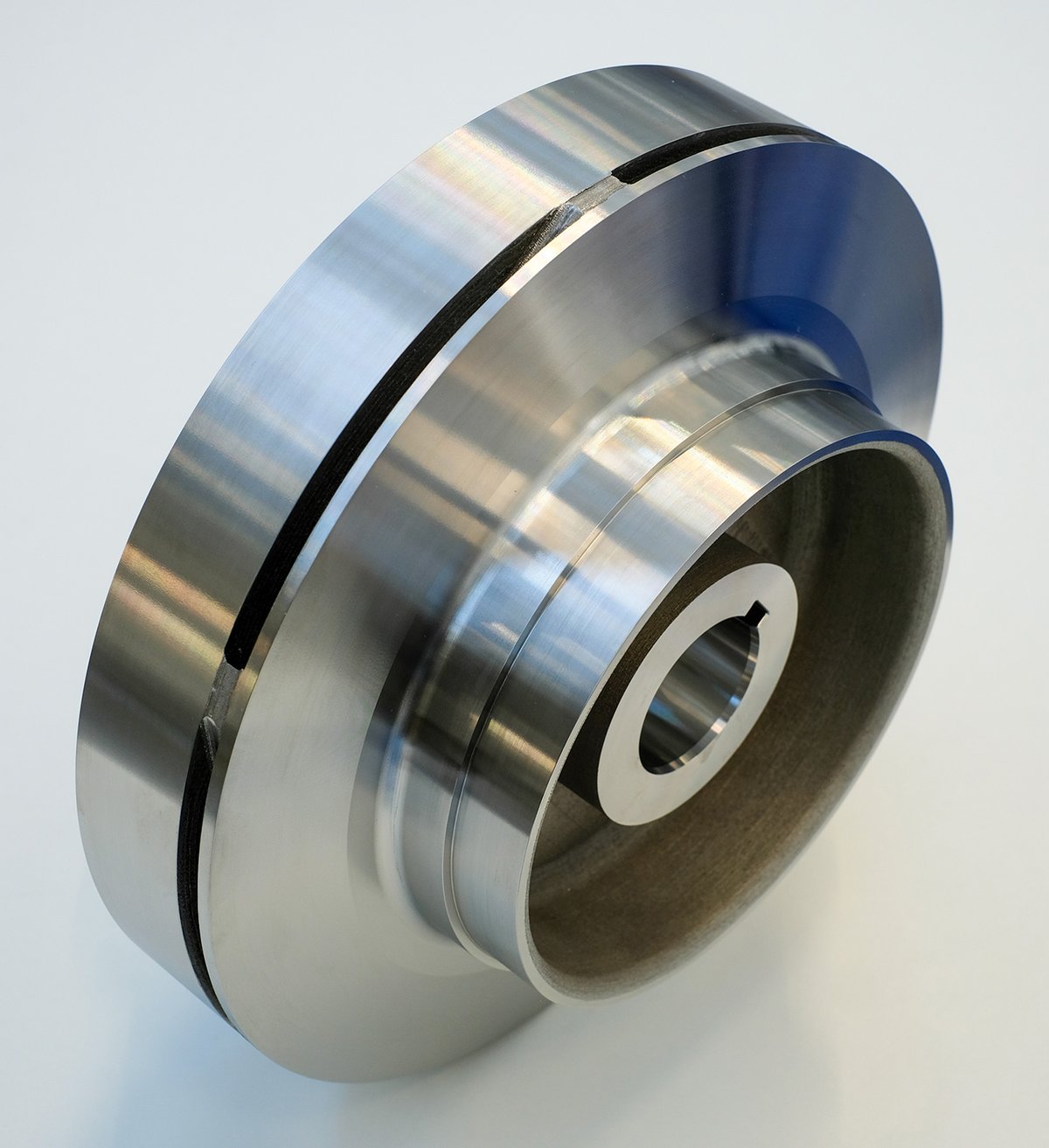

Metal 3D Printing in the Energy Sector

With the increasing adoption of metal AM and its capabilities in energy, oil, and gas markets, the Energy industry has the potential for significant growth. Quality, size and productivity are essential criteria for applications in this sector, which frequently necessitates larger multi-laser build platforms with effective calibration solutions. Specific material qualities are also strongly preferred to meet functional integrity criteria.

"We have found a partner in Additive Industries who not only understands what it takes to employ 3D metal printing in an industrial context, but who also shares our passion for digital technology in order to continuously improve the service we provide to our clients."

Egon Seegers

General Manager service parts - ABB

Why Use Our Technologies?

Open Architecture

- Access to multiple system data streams

- Compliance with the most stringent quality control procedures

- Versatile system design

- Complete flexibility to alter parameter sets

Full Automation

- A fully automated 3D printer

- Eliminates the need for human intervention during

- System calibrations

- Work changeovers

- Component and powder handling

Productivity Leadership

- Open and productive characteristics developed for balanced properties

- Four full-field lasers working with an engineered laminar gas flow

- Equal results (420mm x 420mm) at the highest build rates

Manufacturing Quality

- Highly Reliable and Consistent

- Manufactured by a team with a semiconductor equipment pedigree

Reliable Printing Quality

- Laser-to-laser calibration process

- Completed within minutes

- Ensuring consistent results

Easy and Safe Operation

- Our systems are built with a safety-first approach

- Minimal metal powder exposure

- Meeting all HSE requirements for fire and operator safety

Modularity

- Fantastic ability to scale the level of investment

- A balance between production volume, staffing, and the cost of printing the required materials

Lowest cost per part, automated, and scalable production

Industrial 3D Printing Provides Reliable Quality

Our open product philosophy for additive manufacturing is driven by a desire to serve customers in highly demanding industries. Invest in a versatile additive manufacturing system that can scale to meet your metal part production requirements.