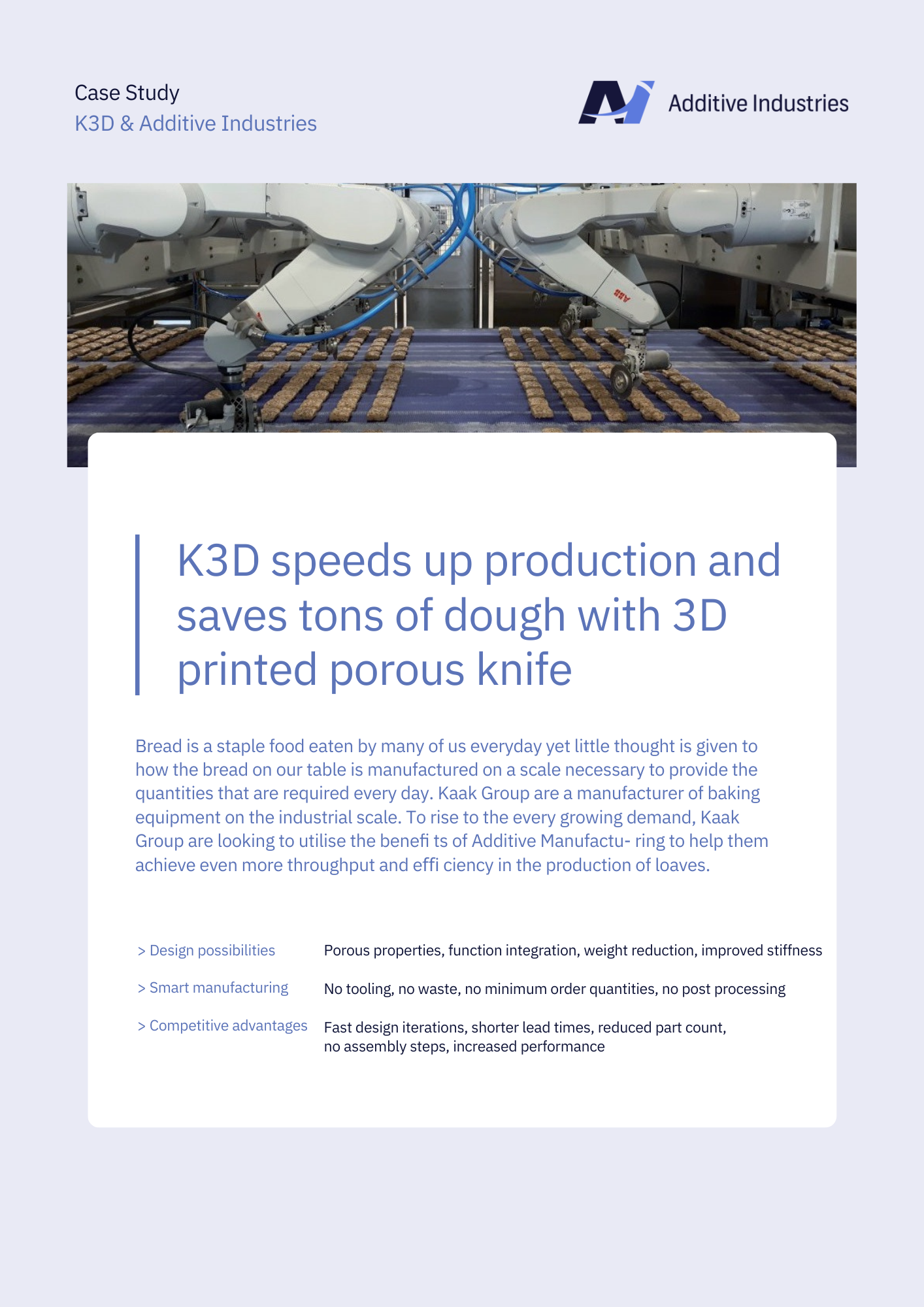

Kaak Group is a leading manufacturer of industrial-scale baking equipment. As the demand for their products continues to grow, Kaak Group is eager to harness the advantages of Additive Manufacturing to further enhance productivity and efficiency in loaf production.

What you will discover in this case study:

- Design possibilities

Porous properties, function integration, weight reduction, improved stiffness

- Smart Manufacturing

No tooling, no waste, no minimum order quantities, no post processing

- Competitive Advantages

Fast design iterations, shorter lead times, reduced part count, no assembly steps, increased performance