Aerospace & defense:

Charting new frontiers in metal 3d printing

Launching a new era of additive manufacturing -

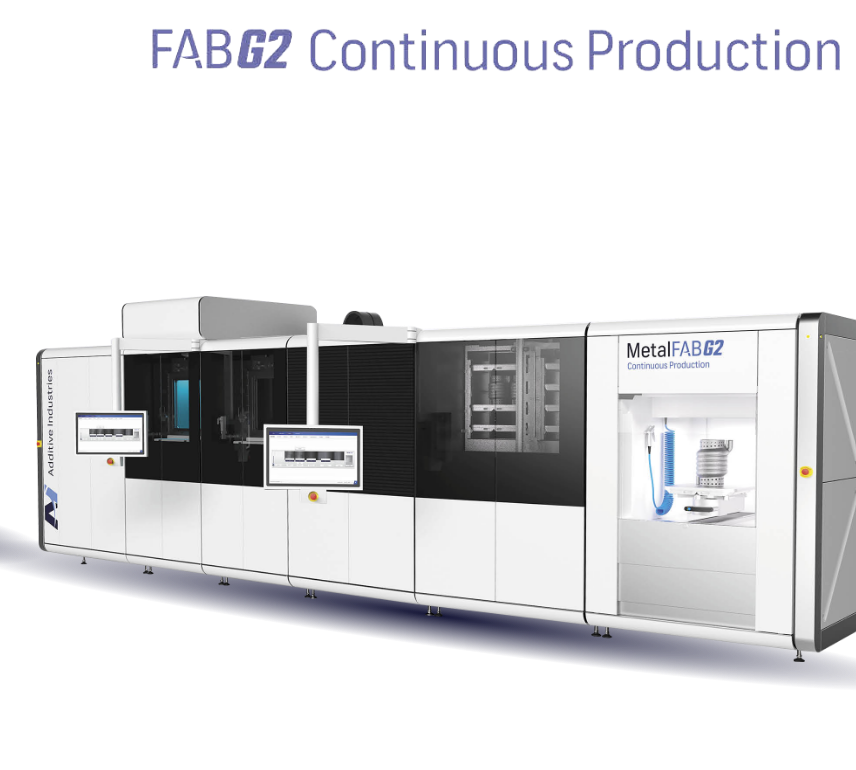

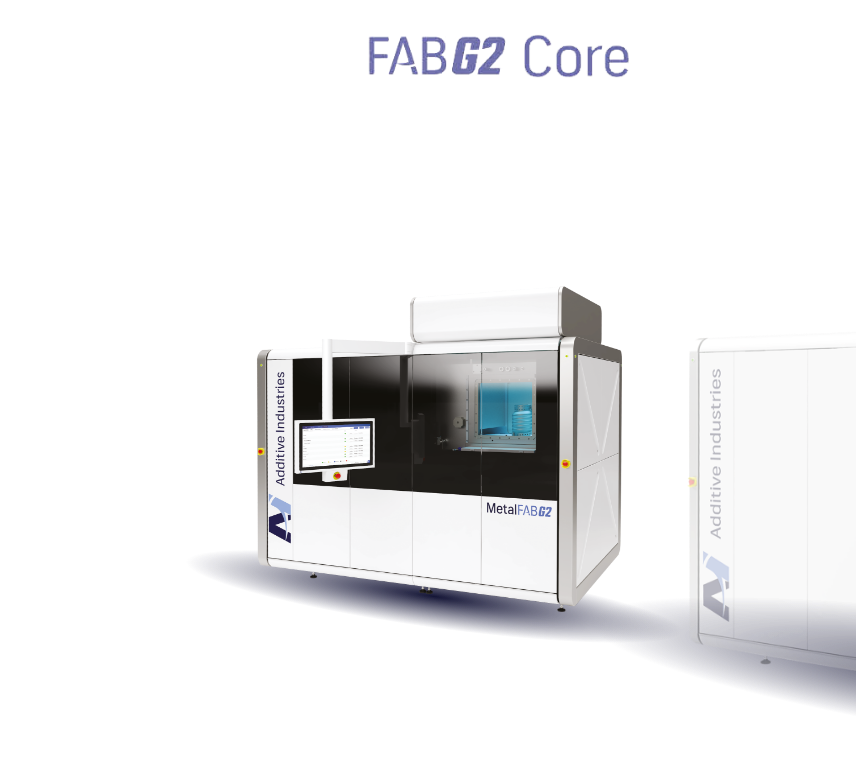

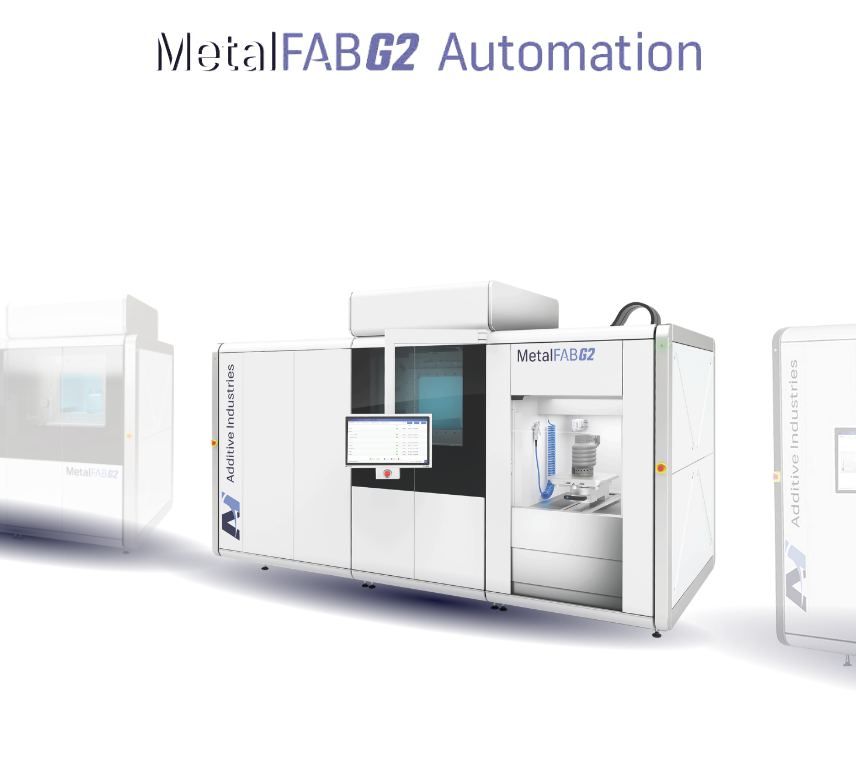

powered by full automation, unmatched laser technology and our commitment to impeccable quality

Explore more

Launching a new era of additive manufacturing -

powered by full automation, unmatched laser technology and our commitment to impeccable quality

powered by full automation, unmatched laser technology and our commitment to impeccable quality

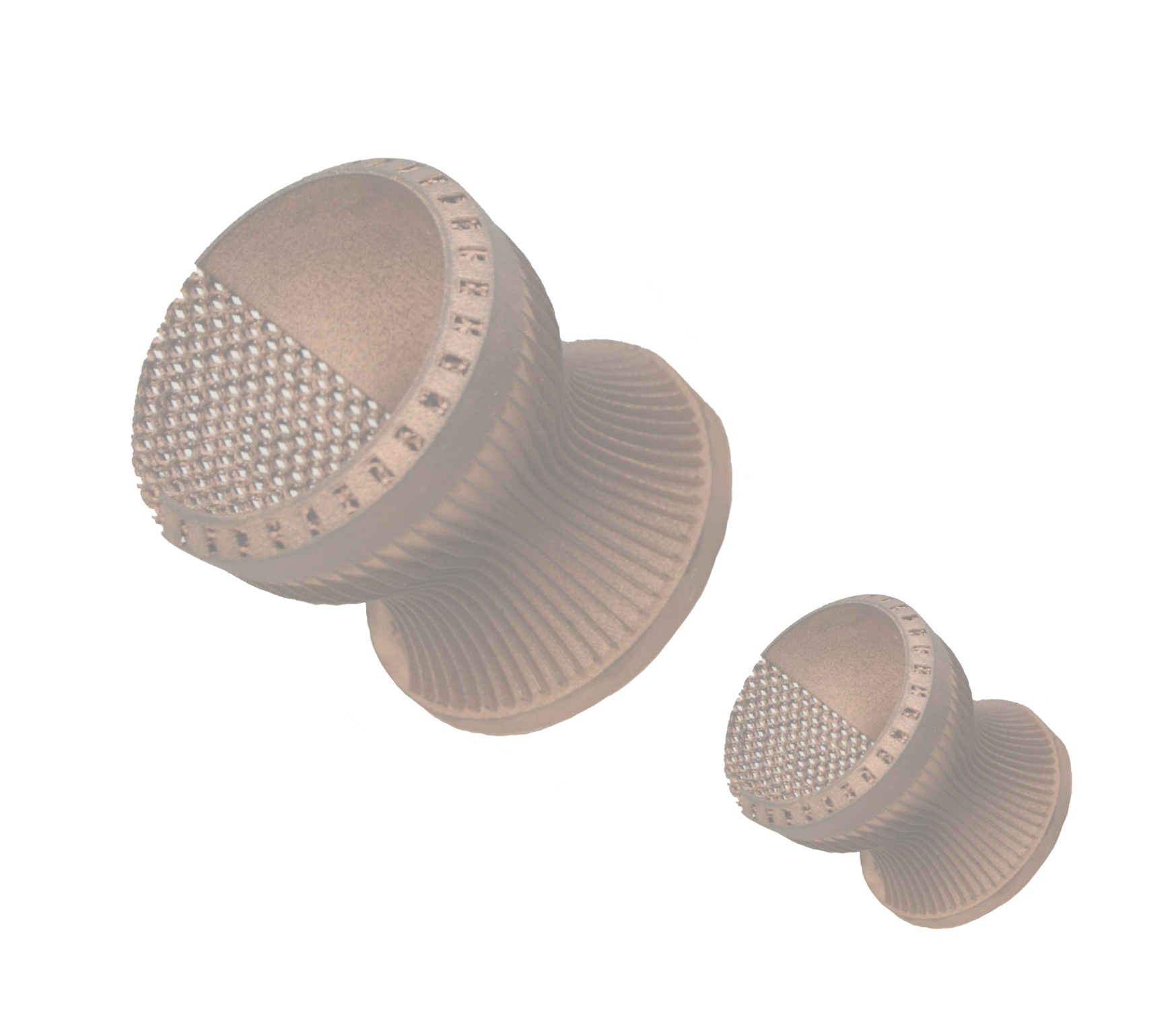

Pushing the boundaries in metal 3D printing

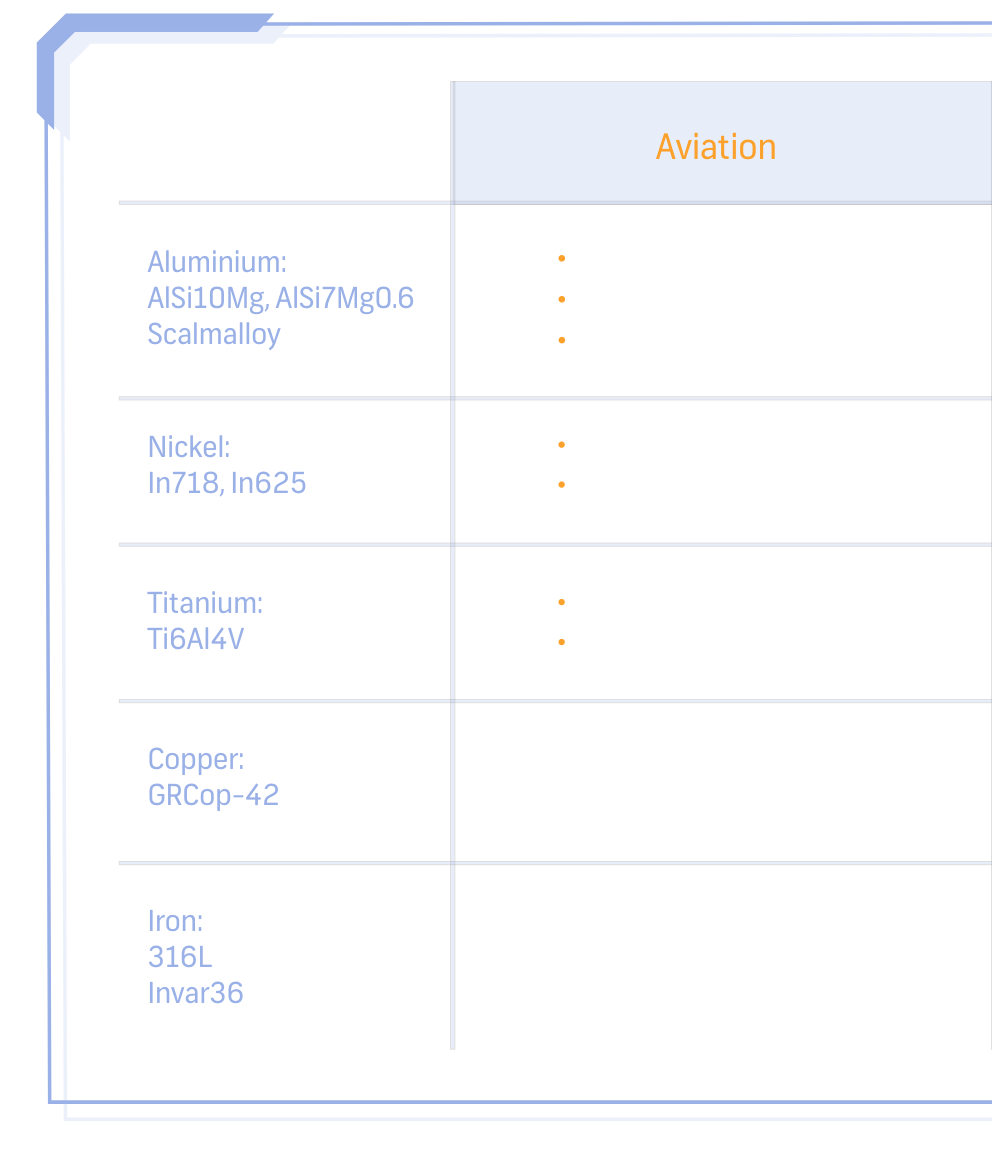

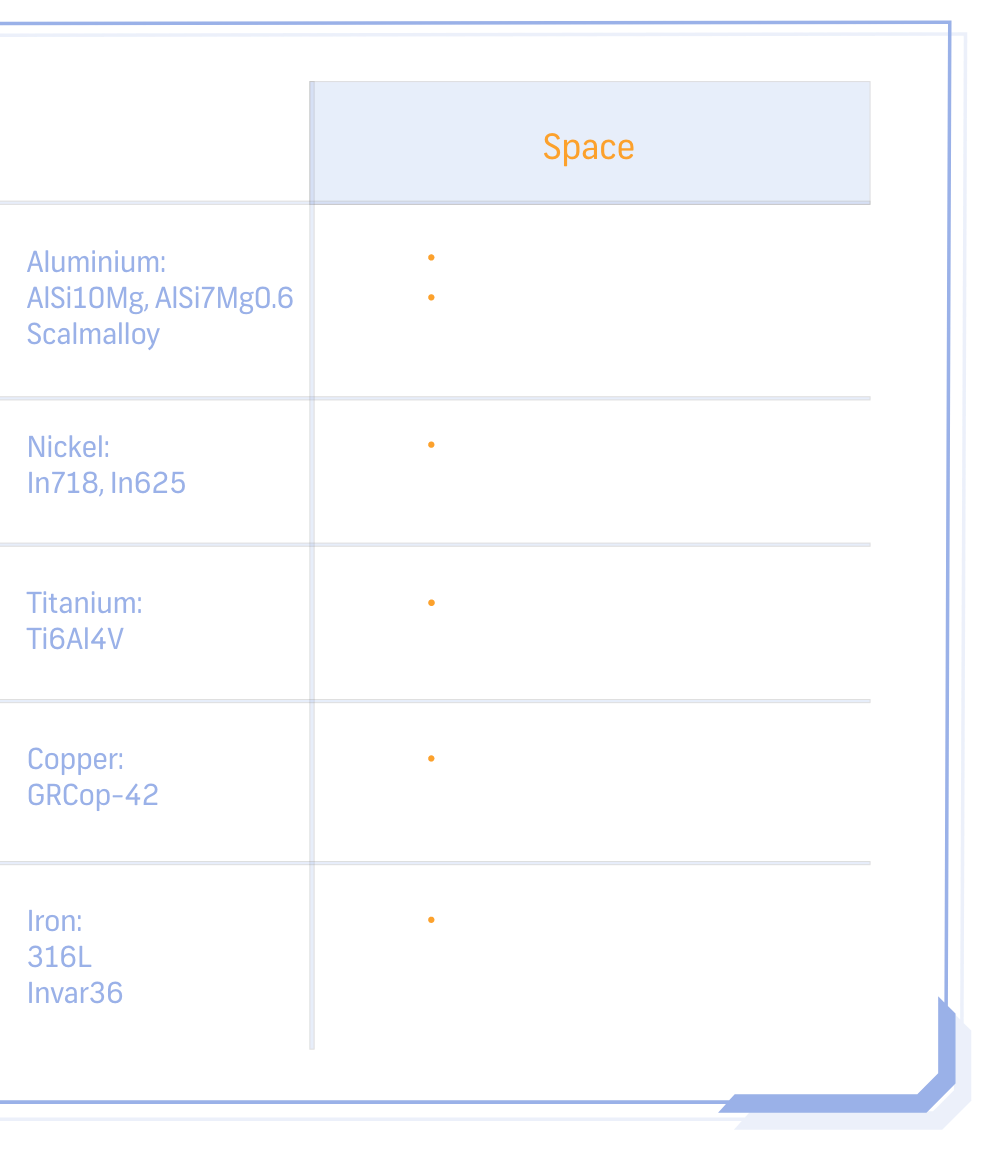

Additive Industries’ metal additive manufacturing (AM) solutions bring unparalleled reliability and productivity to critical applications. With industry-leading features like advanced full-field laser coverage and robust automation, our four-laser technology sets the standard.

Our advanced automation allows for up to eight sequential builds without human intervention. That’s an overall equipment effectiveness of over 90% with just a single shift – a new standard in metal 3D printing.

Brands we work with

-(1).png?width=2000&name=additive-aviation-space-table-01-(1)-(1).png)