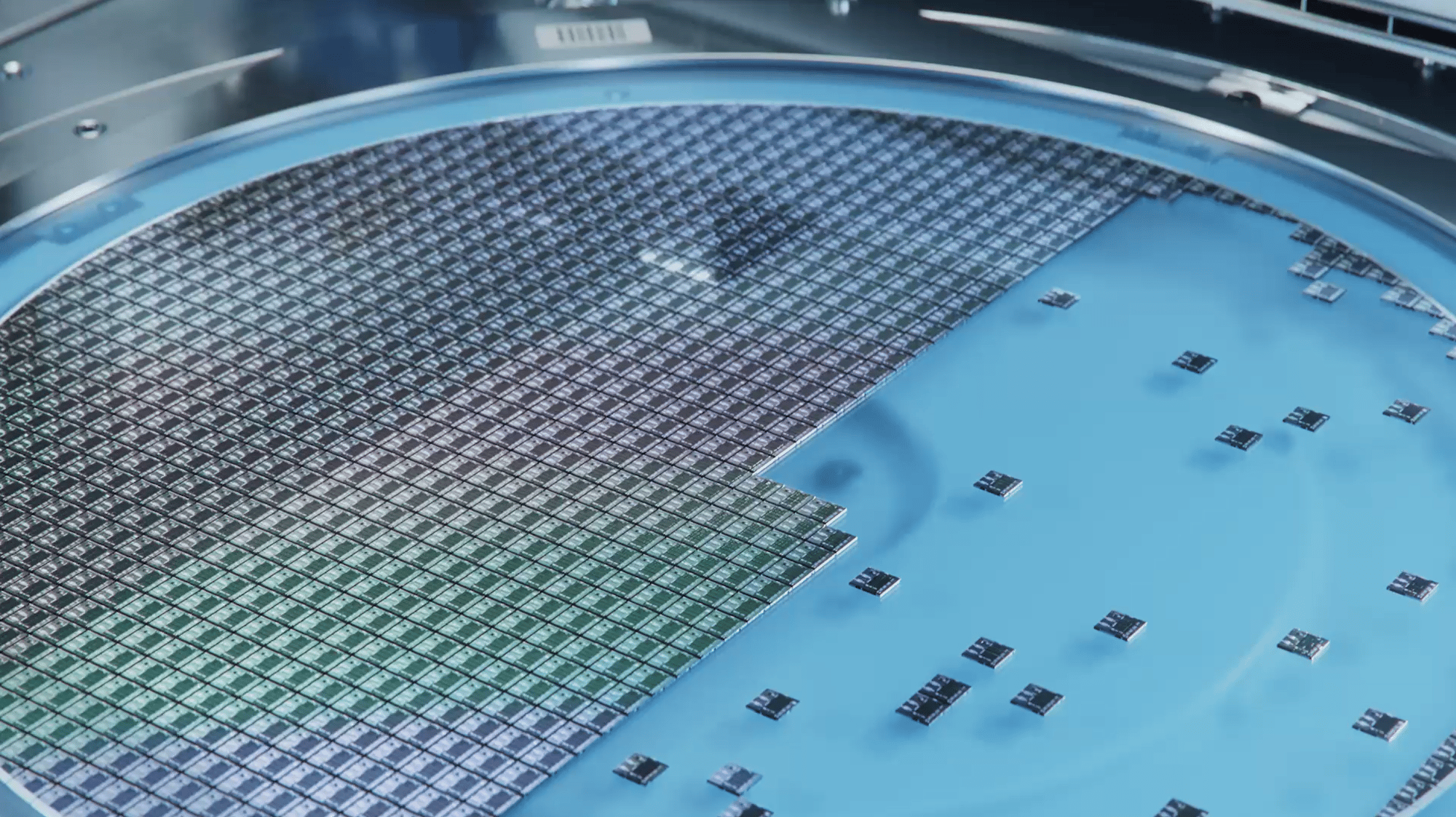

Scaling semiconductor production to serial levels with unmatched reliability and repeatability

Achieve unmatched performance, efficiency, and cost savings with additive manufacturing

Transforming semiconductor production

The semiconductor industry demands constant innovation to meet the complex challenges of microchip production. Companies that fail to integrate AM processes risk falling behind, compromising their competitive edge in the market.

Additive manufacturing (AM) allows for significantly higher design freedom, leading to faster and more accurate systems while driving down costs. This ensures you stay at the forefront of technological advancements and ever-evolving semiconductor industry demands.

Brands we work with