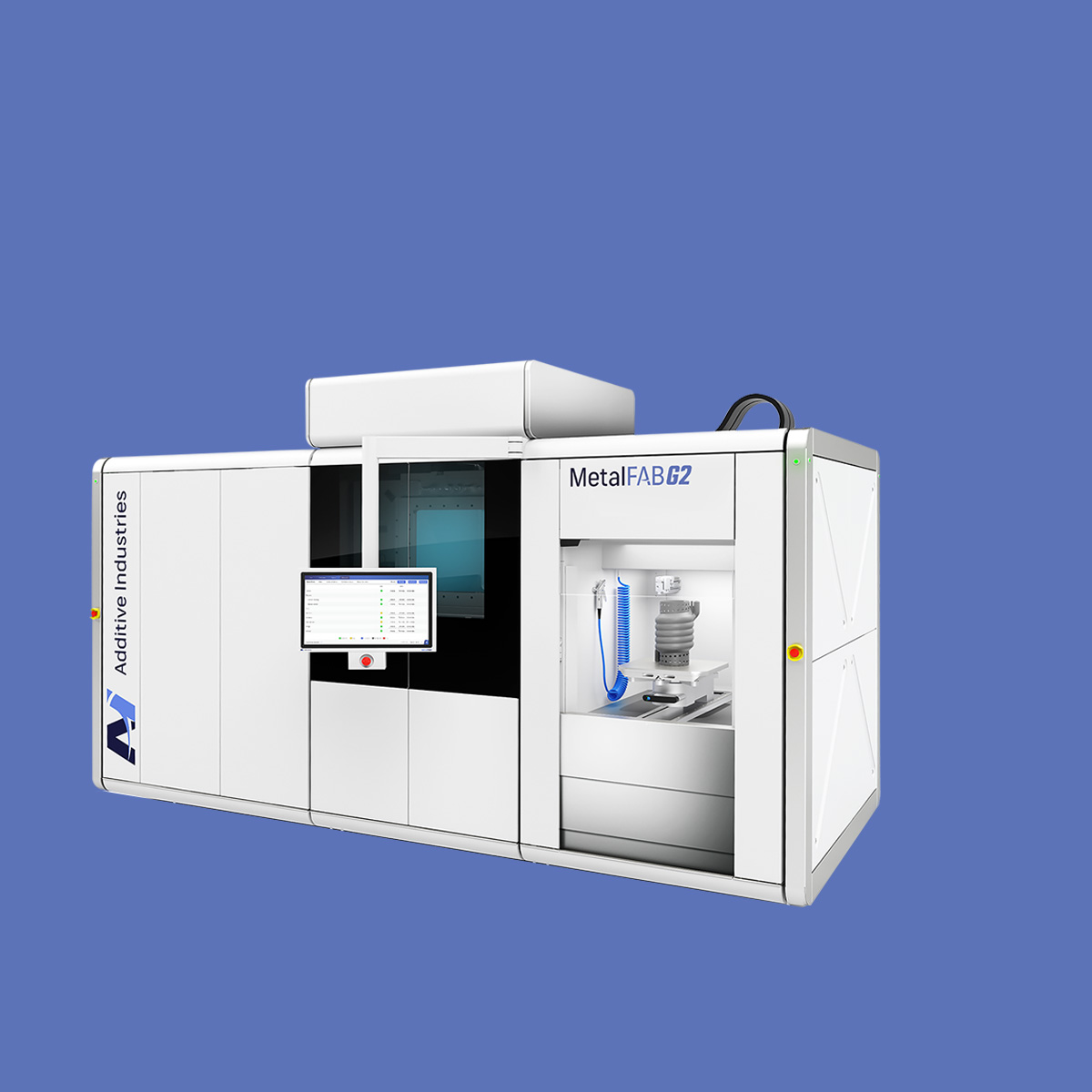

Los Angeles, 25 June 2024 – Additive Industries, pioneer in industrial metal 3D printing, is set to disrupt the metal additive manufacturing (AM) industry with the introduction of its latest innovation, the MetalFab 300 Flex. This latest configuration of metal printer offers a unique on-demand platform size, providing unprecedented flexibility for manufacturers, making metal AM more accessible than ever and the first of its kind in the industry.

Unprecedented flexibility to increase build area on demand

MetalFab 300 Flex signifies Additive Industries' commitment to enable adoption of industrial metal AM. With its proven powder bed fusion (PBF) technology, the MetalFab 300 Flex promises to unlock new possibilities for manufacturers with a range of application/part sizes. Unlike traditional metal AM printers, MetalFab 300 Flex offers a cost-effective entry package with a novel business model in the industry to make it easier than ever for manufacturers to reduce the cost and risk of adopting metal additive manufacturing.

Designed as a cost-effective entry package, the MetalFab 300 Flex will have two full-field 500-watt lasers that can access every corner of a flexible build envelope. The baseline build area will be 11.81 x 11.81 x 15.75in, with the ability to flex access to a larger 16.54 x 16.54 x 15.75in envelope on-demand, either with a monthly or lifetime license. The MetalFab 300 Flex is priced at the same level as a medium frame printer. What sets MetalFab 300 Flex apart is its unparalleled flexibility. An industry first, it’s the only printer that lets users increase their build area on-demand. Combining the more accessible price point of a small printer with the versatility in part size of a larger system.

Proven performance and refined innovation

The MetalFab 300 Flex is not just a new product but a result of years of field-tested performance and customer feedback. This printer ensures reliability and efficiency, but the true innovation of the MetalFab 300 Flex lies in its configuration, specifically designed to simplify the adoption process for new market entrants. Coupled with an innovative business model that allows for flexible scaling.

Attracting new market entrants

MetalFab 300 Flex caters primarily to new entrants in the metal AM market, across industries such as automotive, defense, energy including oil and gas, semiconductor, and industrials. Its cost-effective entry package, integrated powder handling and unique flexibility lower the barrier to entry, making it ideal for companies seeking to manage their financial and technical risk as they embrace and develop metal AM.

By offering flexible build envelope and scalability options, MetalFab 300 Flex provides the platform to innovate and grow, appealing to companies with varying production needs and budget constraints.

Mark Massey, CEO at Additive Industries: “At Additive Industries, we are proud to lead the way in making metal additive manufacturing more accessible and affordable. The MetalFab 300 Flex which is based on our proven metal PBF technology is designed to help our customers manage their technical and financial risk as they grow their AM business. It is specifically aimed at customers who need to be able to build both small and large parts but without incurring the upfront expense of a large printer.”

Specifications MetalFab 300 Flex

- Two 500W lasers, field upgradeable to four lasers to boost productivity

- Flexible scan field volume: 11.81 x 11.81 x 15.75in (300x300x400mm), upgradeable to 16.54 x 16.54 x 15.75in (420x420x400mm)

- Monthly or lifetime licenses available to increase the scan field on-demand

- Price: US$730,000 // €680,000

- Reduced development costs for customers scaling and the ability to scale into full autonomous production

About Additive Industries

Additive Industries is a pioneer in industrial metal 3D printers offering cutting-edge technology that enable customers to industrialize and accelerate their manufacturing processes. As a company, it helps to solve the challenges of the most forward-thinking industry leaders in high demanding sectors, including aerospace, automotive, high tech, and energy. Offering customized automation, modularity and unique calibration options, the company offers smart and highly scalable solutions with a focus on productivity, safety, and sustainability to meet rapidly changing customer demand. Headquartered in Eindhoven (The Netherlands), Additive Industries has service and support centers in the USA.