Eindhoven, Netherlands - 2 September 2024 – K3D has become the international launch customer for Additive Industries’ new MetalFab 300 Flex system by placing an order for two units. The MetalFab 300 Flex, the only metal printer with a flexible build area, was launched at the RAPID+TCT exhibition in Los Angeles. This investment underscores K3D's commitment to expanding its production capabilities while managing financial risk effectively and shows the innovation that Additive Industries brings to the industry by launching this new system.

Strategic investment for optimal growth and minimal risk

K3D, a metal additive manufacturing (AM) service provider based in the Netherlands, was founded in 2014. As a subsidiary of the Royal Kaak (formerly the Kaak Group), a leading manufacturer of industrial bakery production lines, K3D has a rich history of innovation. In 2016, K3D became one of the first customers of Additive Industries, acquiring a MetalFab system to serve the food industry with specialized products that leverage the design freedom of metal AM.

As K3D continues to target a broad range of industries, including aerospace, automotive, tooling, energy (including Oil & Gas), and defense, the need to expand their production capacity has increased significantly. The investment in the MetalFab 300 Flex is a strategic move to accommodate this growth, particularly for stainless steel (316L) and titanium (Ti-6Al-4V) applications.

Key benefits of the MetalFab 300 Flex:

- Flexibility and scalability: The MetalFab 300 Flex offers the flexibility to handle a variety of application sizes without the initial capital expense and ongoing depreciation of a large-frame system.

- On-demand larger build plate access: This feature ensures that K3D can meet customer demands without having to turn away business or seek sub-contractors, thereby minimizing operational risks.

- Scalable expansion: The ability to permanently expand the scan field or add two additional lasers as business grows provides a way to manage financial risk during early-stage business development

Mark Massey, CEO of Additive Industries, commented: "We are delighted to partner with K3D as our launch customer for the MetalFab 300 Flex. Their decision to invest in our latest system highlights their confidence in our technology and their forward-thinking approach to business growth. The flexibility and scalability of the MetalFab 300 Flex will support K3D in meeting their expanding production demands while managing financial risk effectively."

Luuk Wissink, CEO of K3D, added: "We are very pleased to be the launching customer for the MetalFab 300 Flex. This new business model approach from Additive Industries enables us to invest our capital in smaller increments, reducing our financial, commercial, and operational risks. The ability to expand our capacity and manage our footprint as our business grows is crucial, and the MetalFab 300 Flex provides the perfect solution."

For more information about the MetalFab 300 Flex, see here.

About Additive Industries

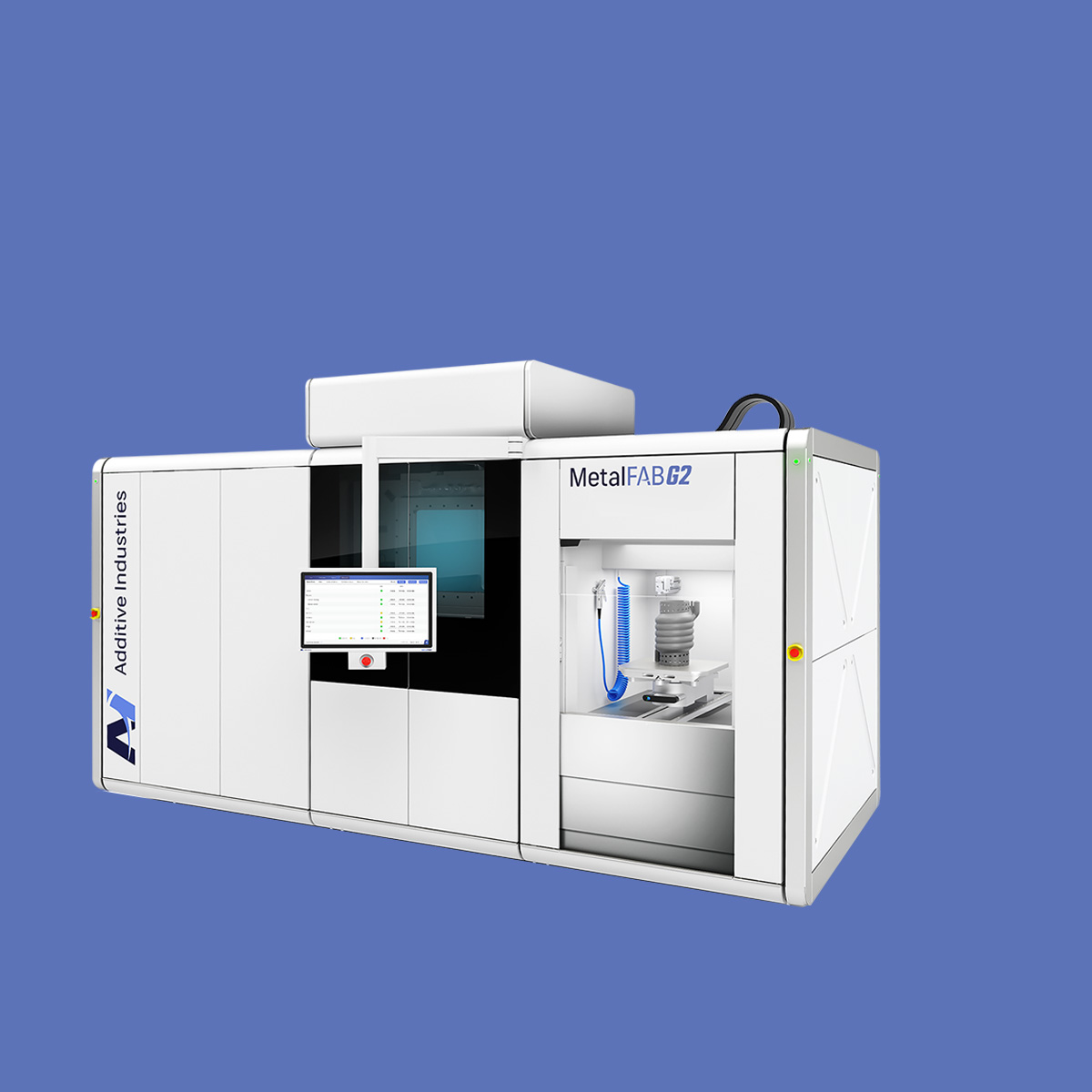

Additive Industries is a pioneer in industrial metal 3D printers offering cutting-edge technology that enable customers to industrialize and accelerate their manufacturing processes. As a company, it helps to solve the challenges of the most forward-thinking industry leaders in high demanding sectors, including aerospace, automotive, high tech, and energy. Offering customized automation, modularity and unique calibration options, the company offers smart and highly scalable solutions with a focus on productivity, safety, and sustainability to meet rapidly changing customer demand. Headquartered in Eindhoven (The Netherlands), Additive Industries has service and support centers in the USA.

About K3D

With more than eight years of expertise in the field of 3D metal printing, we have proven ourselves as masters in metal printing. We specialize in printing parts of any shape or material, from simple to complex geometries. Our capabilities include producing prototypes, small series, and serial applications, with high-quality finishes tailored to customer specifications. Additionally, our expertise extends to industrial parts for specific end markets, such as aerospace, oil and gas, food, high-tech, automotive, robotics, and tooling. With our state-of-the-art production machines, we are the one-stop shop for printing 3D metal parts in various materials. Our printing technology centers are located in the heart of the manufacturing industry: in the east of the Netherlands and the Brainport region of Eindhoven. 3D printing contributes to the world of tomorrow by reducing waste, promoting the responsible use of materials, and minimizing transport needs.