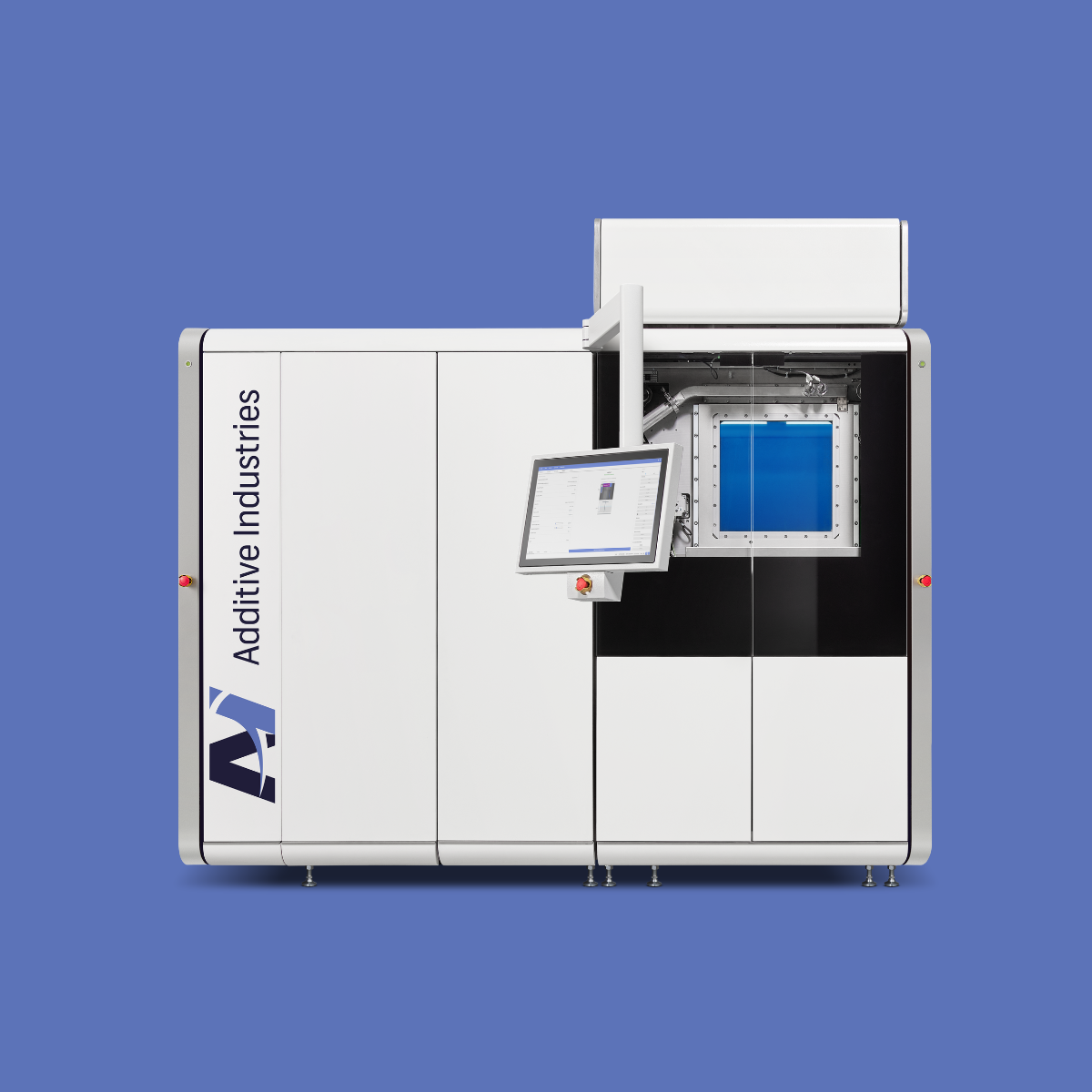

Embrace full automation - Never interrupt your print operation again:

Experience uninterrupted operation with our system’s full automation that extends even to post-printing processes. An automated build plate exchanges and levels builds and prepares subsequent jobs, fostering a seamless, automated cycle. This continuous flow promotes high productivity, elevates efficiency and ensures consistent quality.

.svg.png?width=305&name=BMW_logo_(gray).svg.png)