April 2, 2020

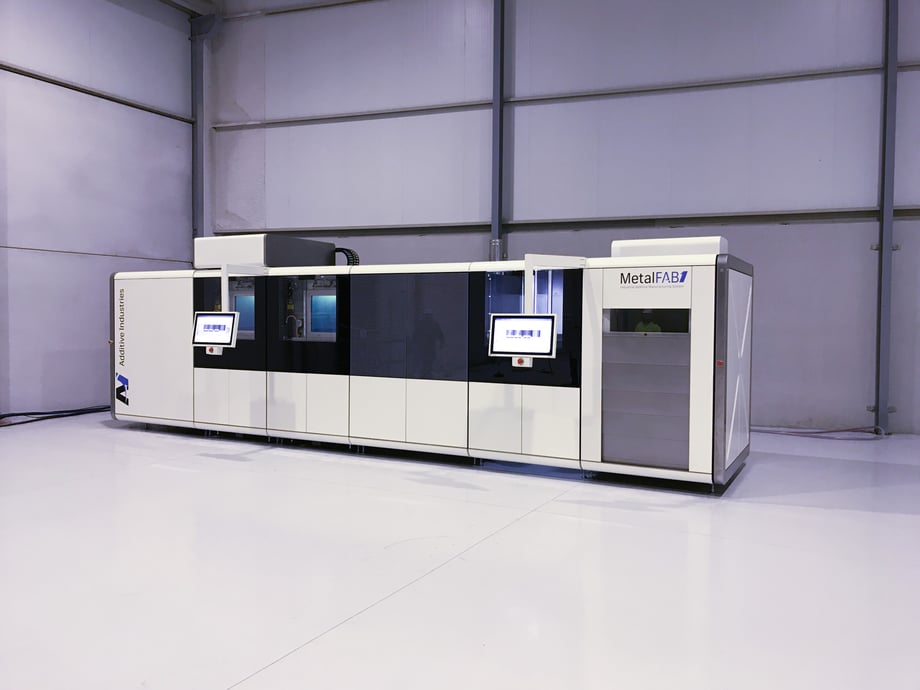

ArcelorMittal and Additive Industries take the lead in large spare part printing for the steel industry

Through metal 3D printing, ArcelorMittal has been able to print on-demand ready-to-use spare parts. Collaboration with Additive Industries in recent years has...