November 4th, 2025 – Eindhoven, the Netherlands

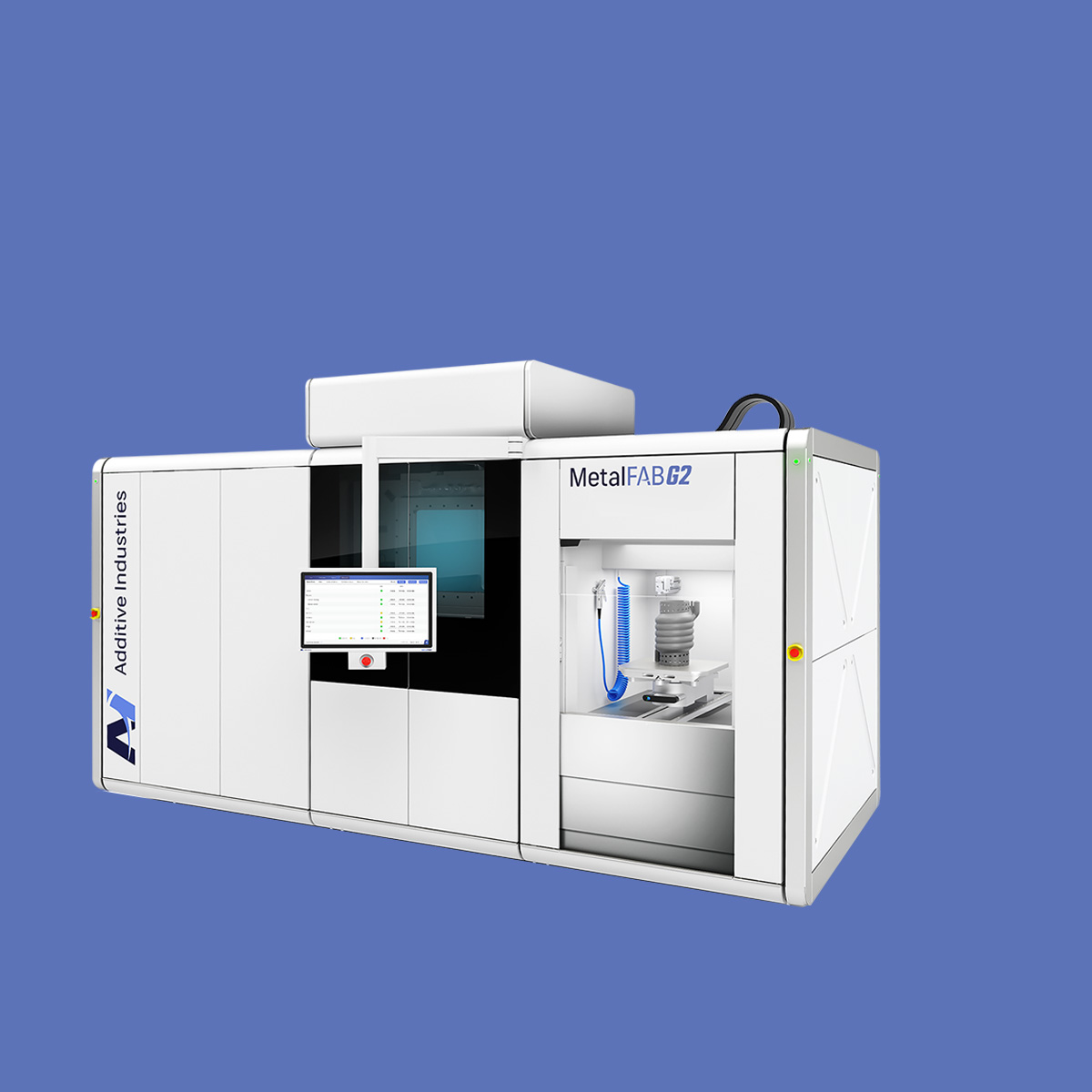

Additive Industries announce the launch of the MetalFab 420K –a 4 x 1kW laser powder bed fusion system designed to unlock demanding AM production applications.

Additive Industries, a leader in industrial additive manufacturing equipment, today announced the launch of its latest innovation: the MetalFab 420K, a new automated and modular additive manufacturing machine equipped with 1 kilowatt lasers, designed to enable users to further push the boundaries of metal 3d printing with higher productivity rates whilst maintaining high material quality levels. Underpinning the system, Additive Industries have developed a range of technological features to meet the demands of key market sectors such as space, aerospace, automotive and high-tech which include:

- 4x full-field lasers with 1kW power, each accessing the full 420 x 420 x 400mm build volume

- Optimised, highly homogenous and high velocity gas flow to ensure consistency and quality across the powder bed, enabling high laser power and scan speeds to be achieved without compromise

- Variable beam diameter as a process parameter, calibrated from 100 to 500μm, creating opportunities for advanced material and process development

- Open architecture giving users full freedom to develop their own process parameters to push productivity further or develop parameters for hard to process materials

- Automated laser calibration and in-build laser-to-laser alignment

- Advanced oxygen and humidity controls and tracking to reduce powder ageing and improve part quality

- New permanent filter design reduces maintenance intervals and enables improved waste handling without print interruption

- Fully enclosed and automated powder extraction, sieving and transportation ensuring operator safety and material quality control as standard

- Allows onsite expansion of capacity through modular design for enhanced degree of automation (up to 8 jobs run automatically without operator input), or flexibility (up to 3 materials installed simultaneously with multiple additive manufacturing cores installed in series)

‘Our objective at Additive Industries is to develop manufacturing systems which provide market leading quality and productivity for manufacturers working with additive manufacturing technology – this is the philosophy which drove our development of the MetalFab 420K’, said Mark Massey, CEO of Additive Industries. ‘Based on the feedback of our valuable global customer base we have built this new system from the proven DNA of our MetalFab product portfolio with a key focus on the needs of our demanding users in the space, aerospace, automotive and high-tech sectors who are looking to push productivity further in their manufacturing operations, where no compromise in quality is acceptable. The MetalFab 420K delivers this.’

Niels Cruts, Manager Technology added ‘Our R&D team has delivered a range of technical innovations implemented in the MetalFab 420K which, with its open architecture will allow our users to further push the limits of our technology to deliver even more challenging applications and reduced cost per part. The system has undergone an extensive development and testing period, including a beta program where it has been run in a demanding production environment with one of our key customers in the space sector, producing production parts.’

After a rigorous 6 month beta test program, where the system was placed on the production floor of a key US based customer in the space sector, and productivity levels exceeded expectations, the MetalFab 420K is commercially available from today, with orders currently being taken for Q2 delivery slots.

<End of press release>

About Additive Industries

Additive Industries, headquartered in Eindhoven (the Netherlands), is a pioneer in industrial metal 3D printers offering cutting-edge technology that enable customers to industrialize and accelerate their manufacturing processes. As a company, it helps to solve the challenges of the most forward-thinking industry leaders in high demanding sectors, including aerospace, automotive, high tech, and energy. Offering customized automation, modularity and unique calibration options, the company offers smart and highly scalable solutions with a focus on productivity, safety, and sustainability to meet rapidly changing customer demand.

Contact

Andrew Hawkins, Product Marketing Manager

E-Mail: a.hawkins@additiveindustries.com

Additive Industries b.v.

Achtseweg Zuid 155, NL 5651 GW Eindhoven, The Netherlands

P.O. Box 30160, NL 5600 GA Eindhoven, The Netherlands

www.additiveindustries.com