Welcome

to the fast lane

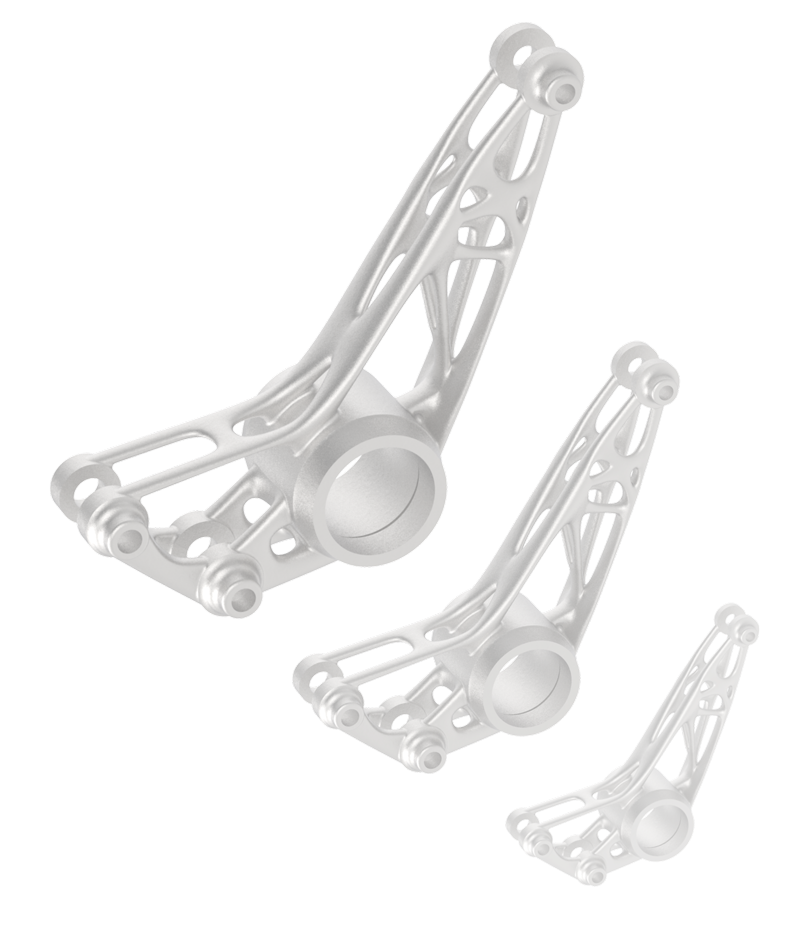

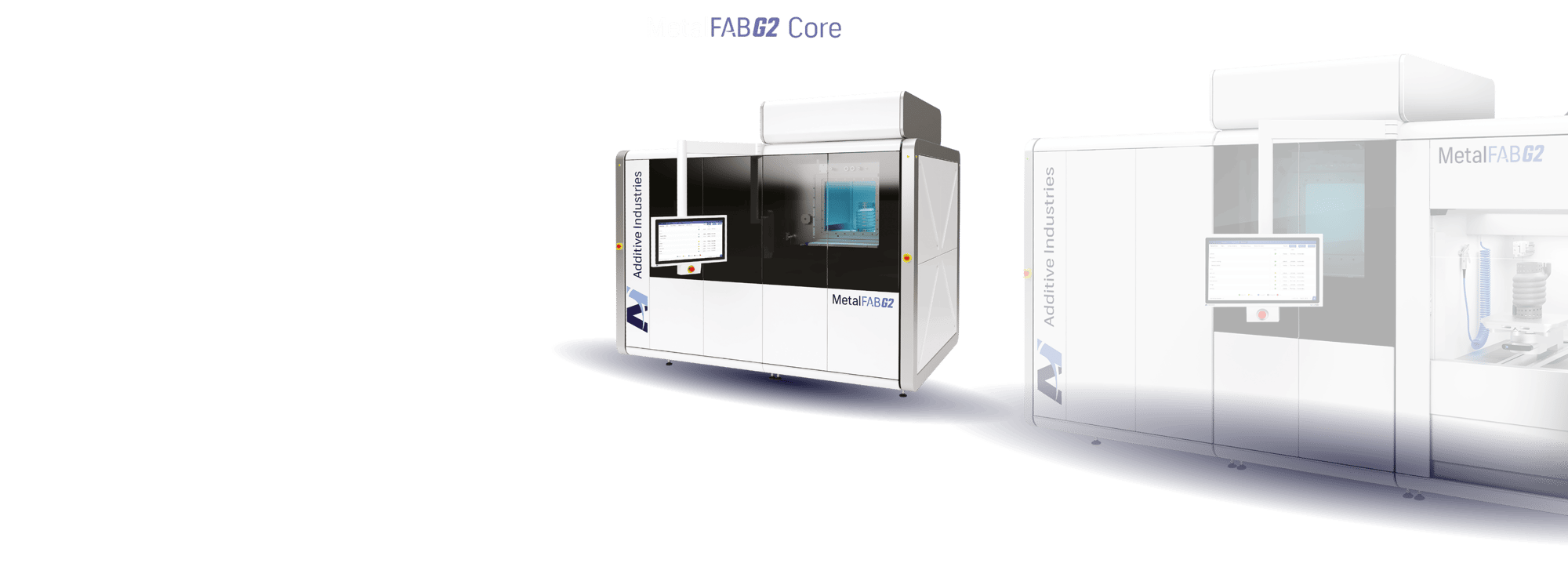

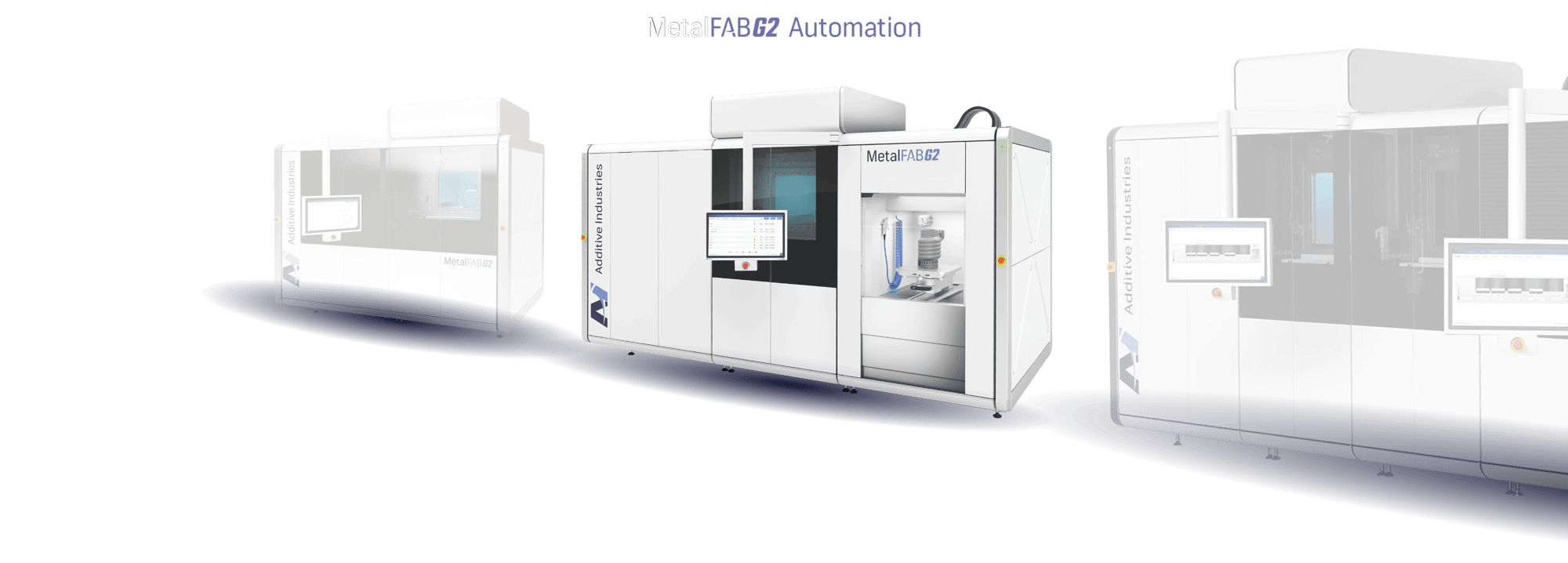

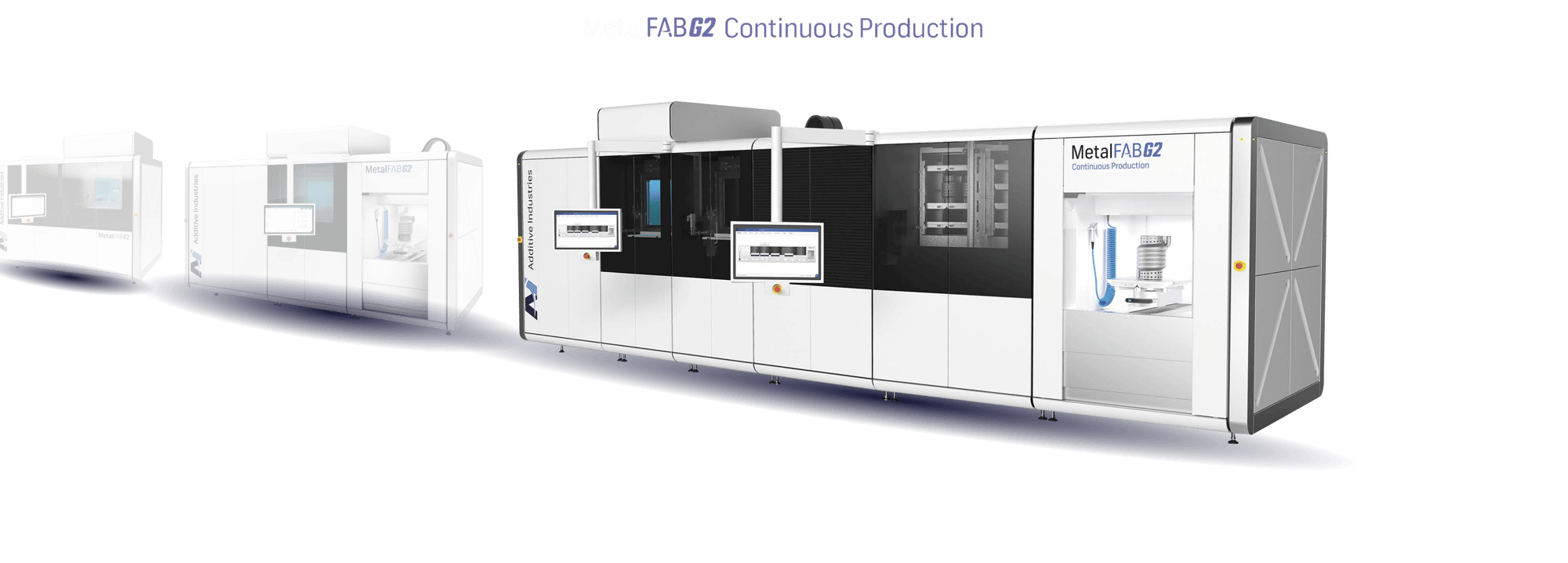

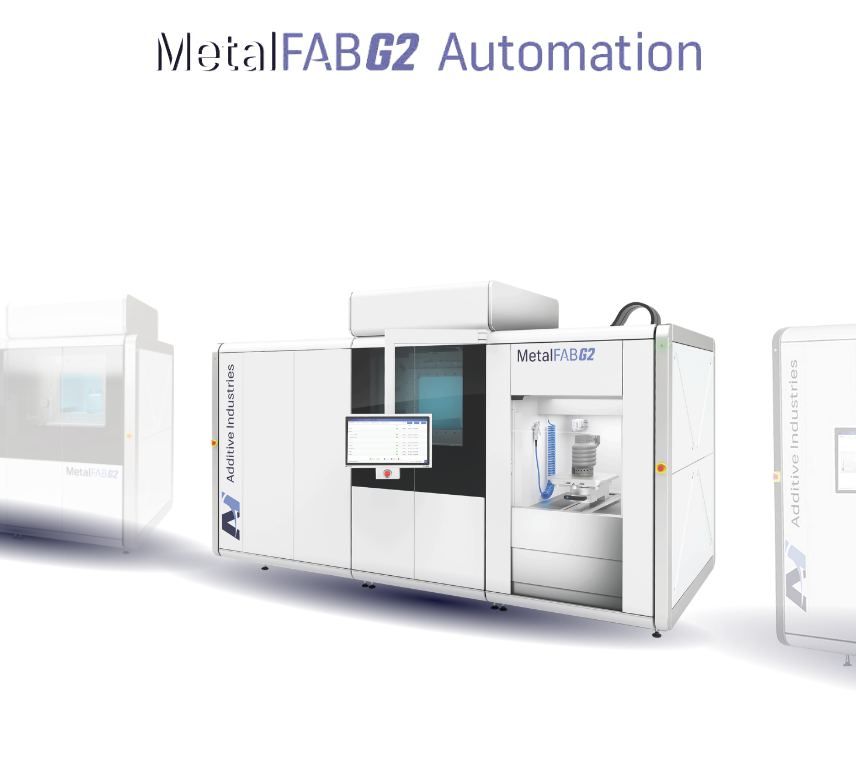

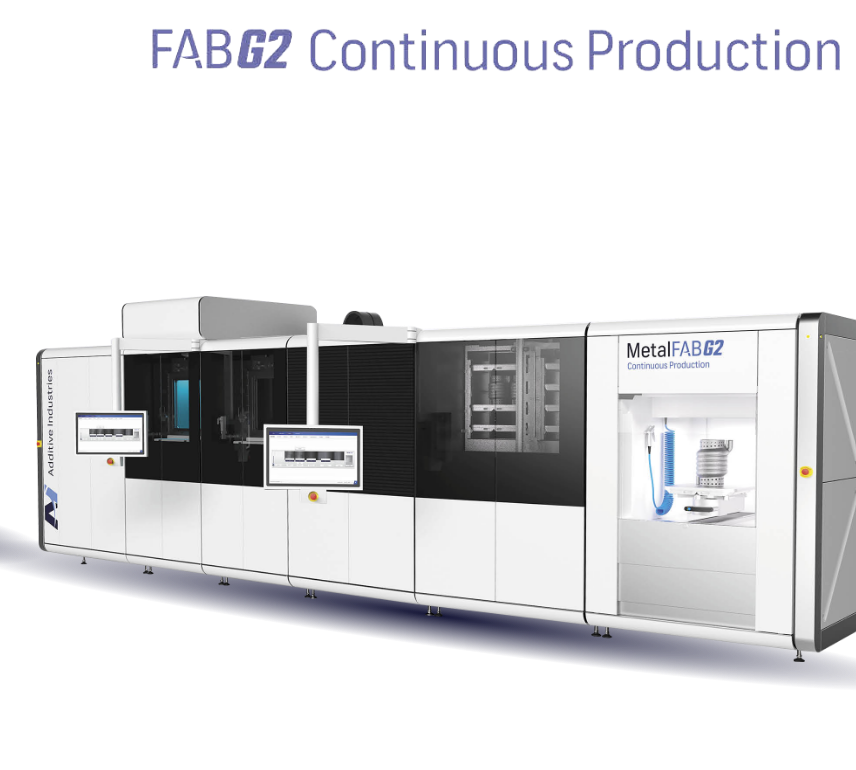

This is modular, fully automated metal 3D printing

the future of automotive manufacturing

Discover more

the future of automotive manufacturing

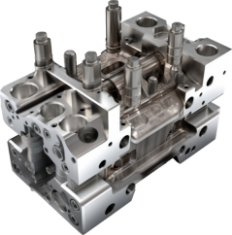

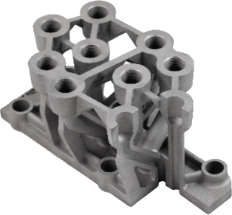

Revolutionising industrial 3D printing

Additive Industries offers automated, highly scalable metal additive manufacturing (AM) solutions that empower businesses to industrialise and accelerate their manufacturing processes.

Our metal AM printers enable companies to drive innovation by enhancing quality control, speed and safety, all backed by our impeccable service.

With their state-of-the-art automation, industry-leading uptime and unique modularity, it's no wonder that KICK Sauber F1® Team, BMW and VW have adopted our printers for additive manufacturing applications.

Brands we work with

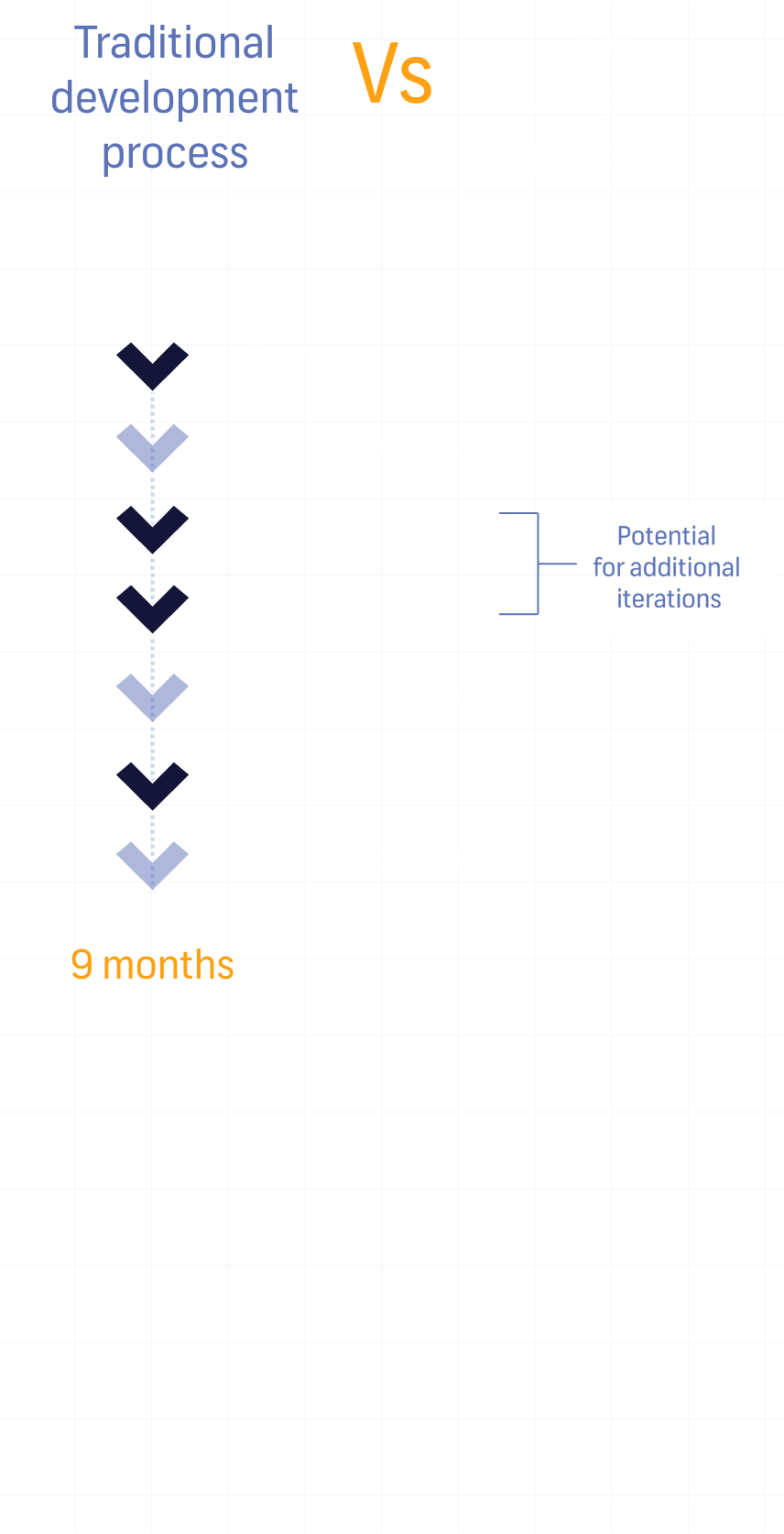

.png?width=2000&name=traditional-vs-am-02%20(1).png)

.png?width=856&height=1674&name=traditional-vs-am-mobile-01%20(1).png)