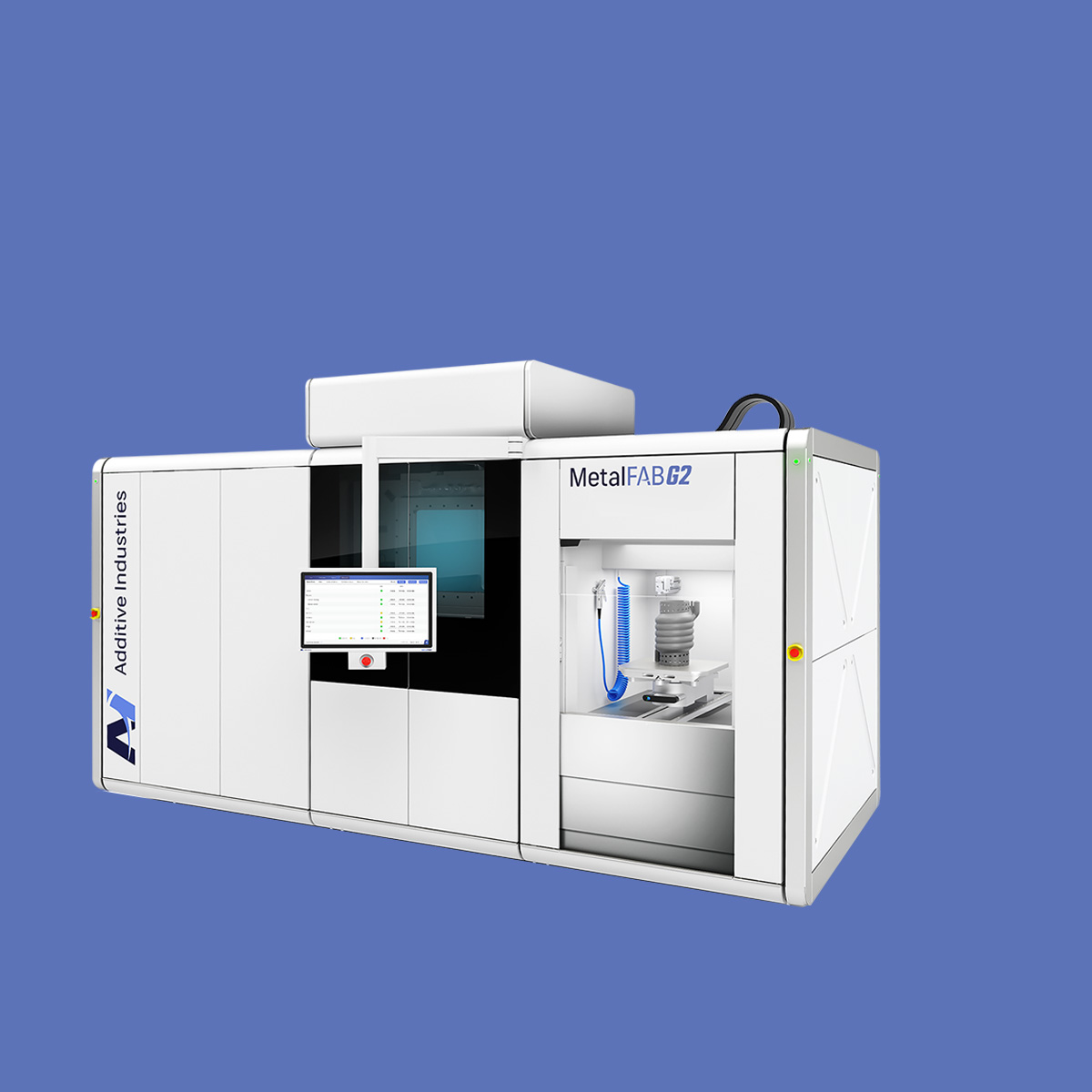

On Wednesday, November 29, an official handover of the first industrial AM system to the Sauber F1 Team took place in Hinwill (Switzerland). The Sauber F1 Team has officially taken delivery of their first MetalFAB1 system as part of the three-year technology partnership. Additive Industries founders Jonas Wintermans and Daan Kersten handed over the industrial additive manufacturing system to Axel Kruse, Production Director, and Christoph Hansen, Chief Wind Tunnel Production, from Sauber Motorsport AG. Having over 10 years of experience in Additive Manufacturing in plastics, the Sauber F1 Team is now expanding its 3D printing competences and capabilities to metals. The investment in two MetalFAB1 systems allows them to reduce their cycle time in manufacturing of innovative parts for their own wind tunnel models, F1 race cars as well as third-party business. An official Press Release and pictures can be found on the Press Page.