Industrial metal AM users are consistently driving OEMs to discover innovative methods that enhance productivity and reduce the cost of parts. In order to increase the material consolidation rate, the radiation energy exposing the powder bed must also increase. This is typically achieved by processing with higher laser power and/or using multiple lasers to sustain multiple melt pools. The use of multiple lasers working together on a single part requires good overlay accuracy between lasers. Even on a system where all lasers have full field capability and no stitching is necessary, laser to laser positioning overlay is vital for part quality.

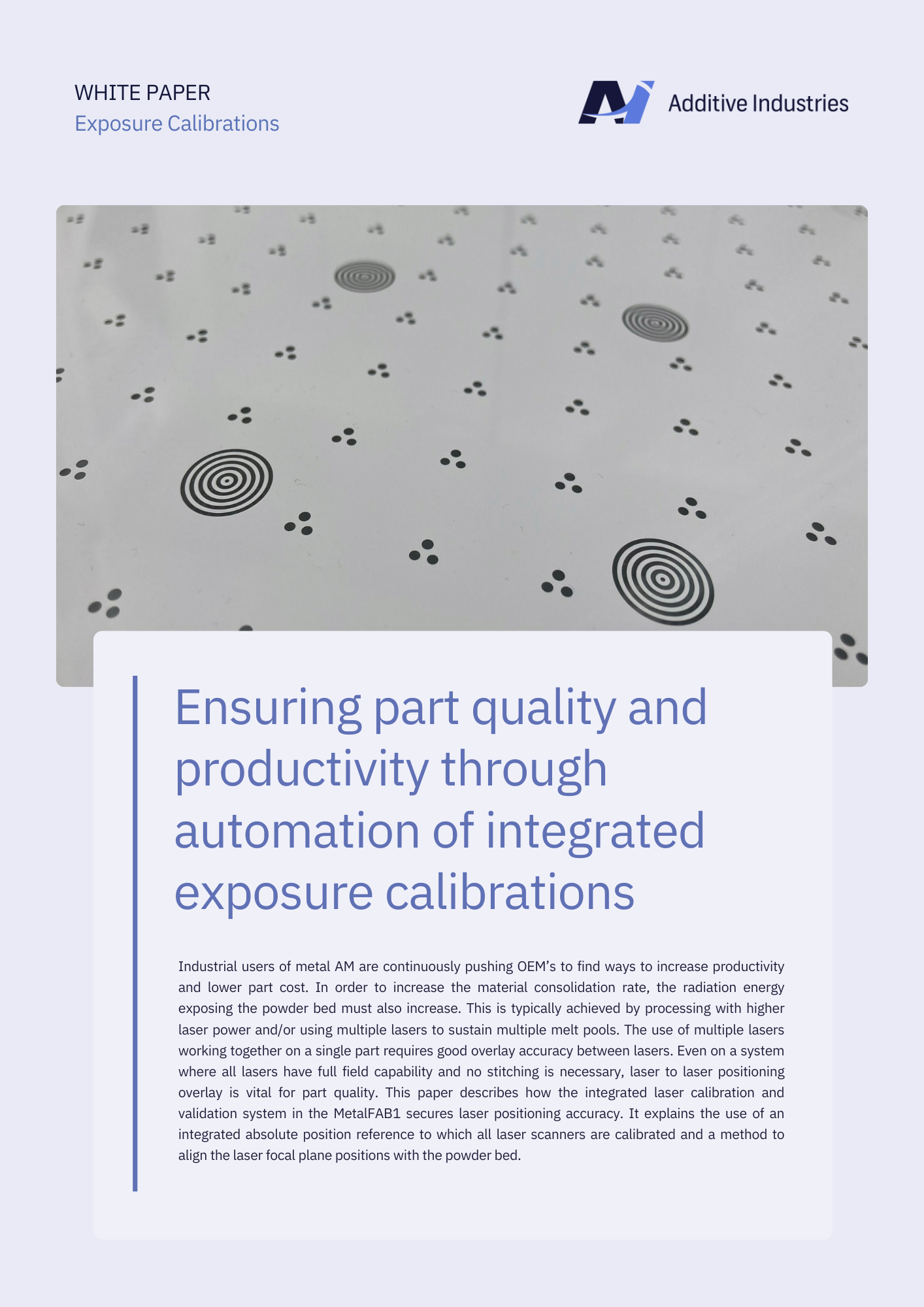

Find out how the integrated laser calibration and validation system in the MetalFAB1 secures laser positioning accuracy. It explains the use of an integrated absolute position reference to which all laser scanners are calibrated and a method to align the laser focal plane positions with the powder bed.