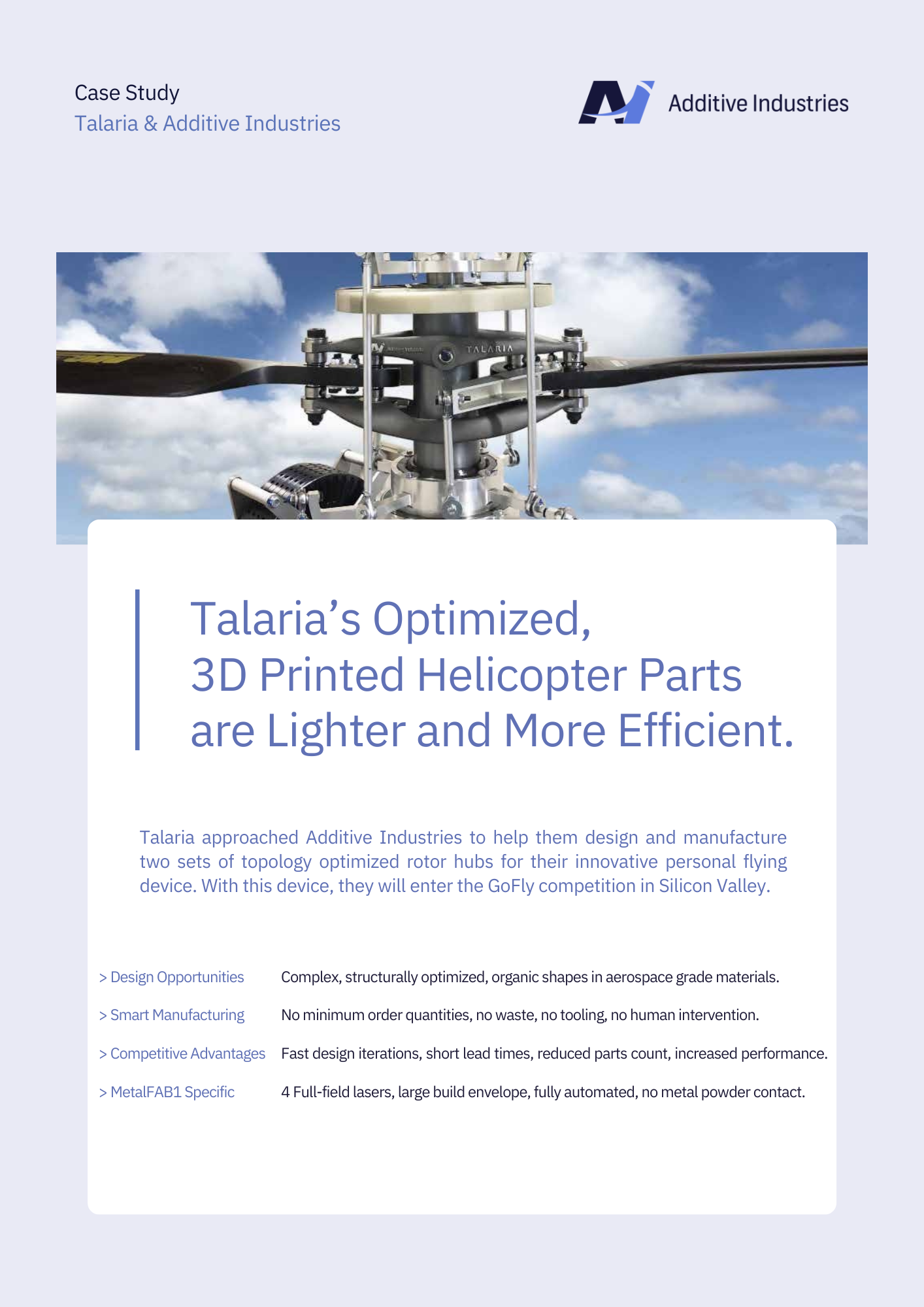

Talaria approached Additive Industries to leverage their expertise in designing and 3D printing rotor hubs that are optimized for their innovative personal flying device. By harnessing this advanced technology, Talaria aimed to make a significant impact in the aviation industry through their participation in the GoFly competition in Silicon Valley. This fascinating case study delves deep into the remarkable accomplishment made possible by the MetalFAB1.