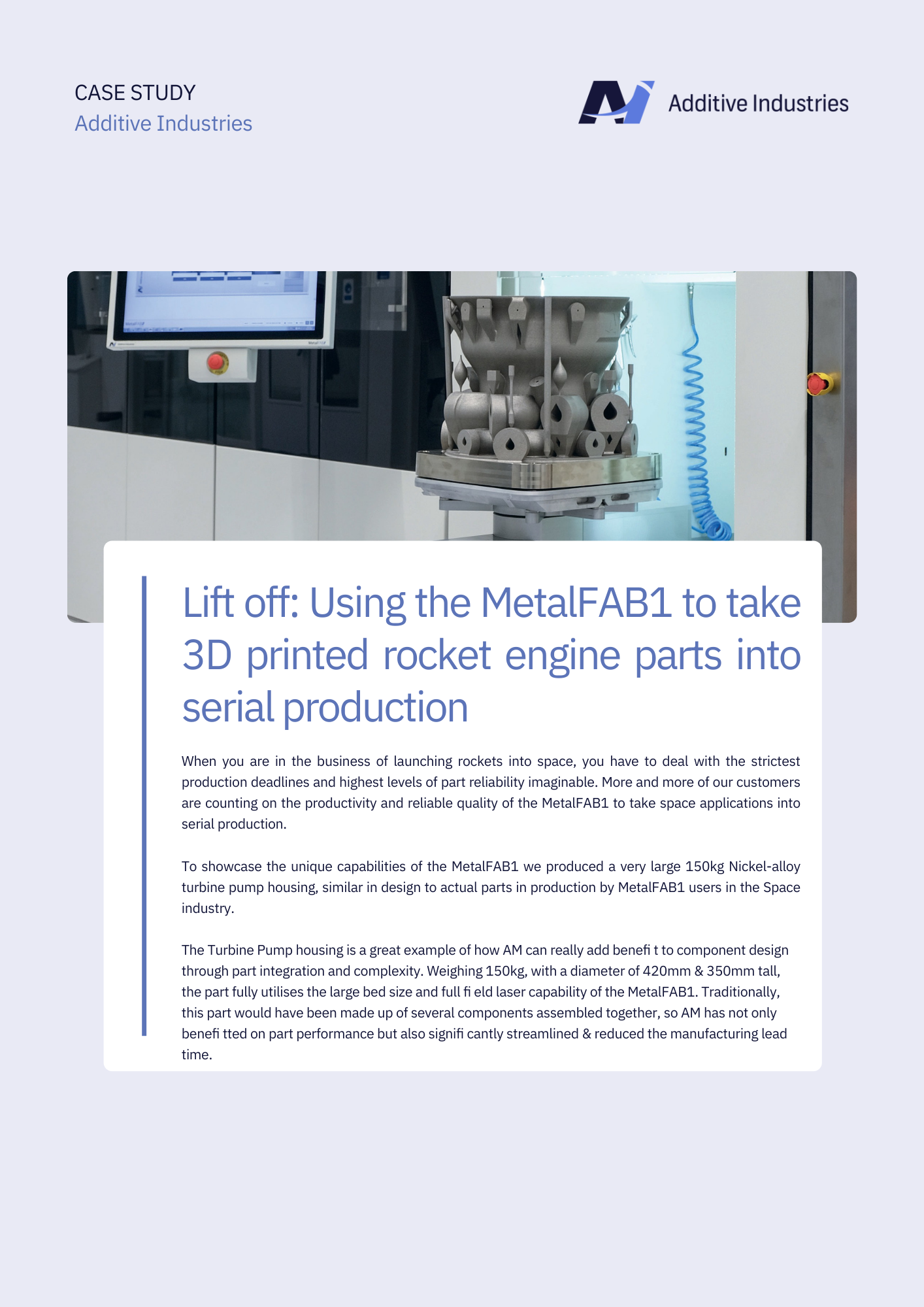

The Rocket Turbine-Pump Housing serves as a remarkable demonstration of the immense value additive manufacturing brings to component design by integrating parts and embracing complexity. Weighing in at 150kg, with dimensions measuring 420mm in diameter and 350mm in height, this part optimizes the MetalFAB1's large bed size and full field laser capability to the fullest extent. In the past, constructing this part involved assembling multiple components together, but additive manufacturing has not only enhanced part performance but also dramatically streamlined the manufacturing process, significantly reducing lead times.