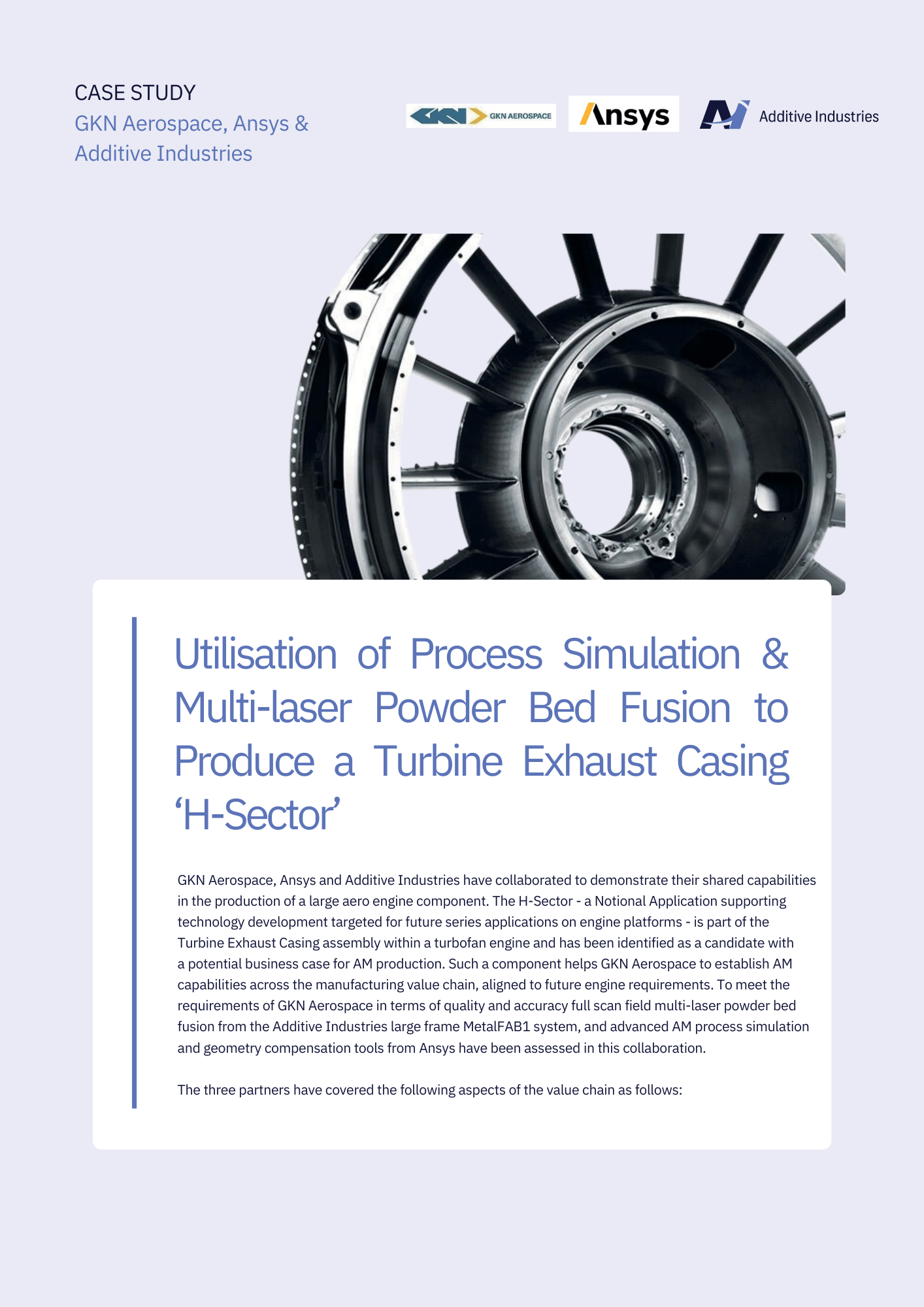

GKN Aerospace, Ansys, and Additive Industries have joined forces to showcase their collective expertise in producing a significant component for aero engines. The H-Sector, a notional application aimed at advancing technology for future engine platforms, is a crucial part of the Turbine Exhaust Casing assembly in a turbofan engine. It has been identified as a potential candidate for additive manufacturing (AM) production, presenting a promising business opportunity. By incorporating this component, GKN Aerospace strengthens its AM capabilities throughout the manufacturing value chain, aligning with future engine requirements. In this collaboration, the Additive Industries MetalFAB1 system's full scan field multi-laser powder bed fusion, along with Ansys' advanced AM process simulation and geometry compensation tools, have been thoroughly evaluated to meet GKN Aerospace's exacting standards for quality and precision.