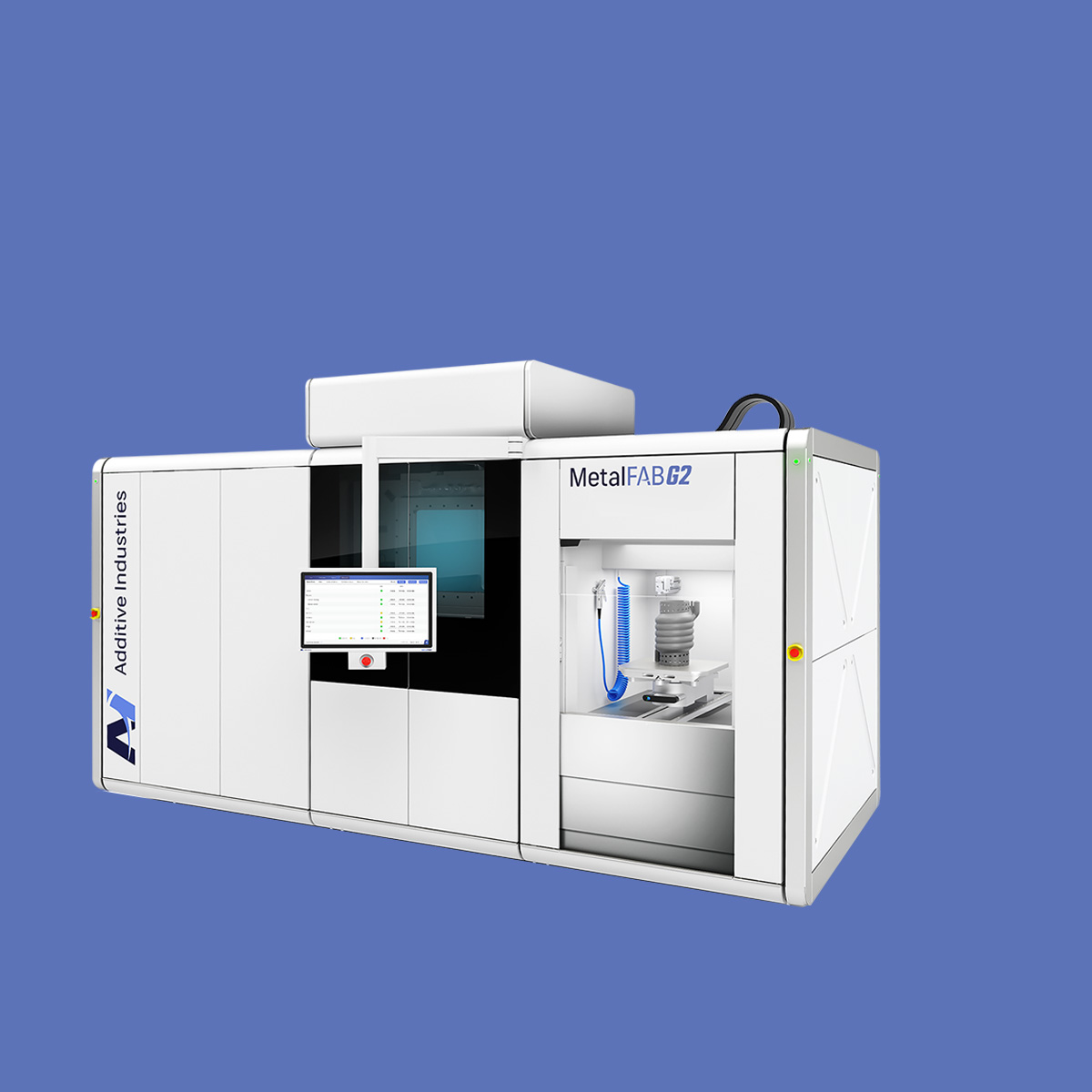

We are very proud to announce the purchase of 6 MetalFAB1 systems by a prestigious aerospace company located in California. This firm order validates the Additive Industries’ concept of production-based metal powder bed fusion systems for maximum overall equipment efficiency. When the order for six machines arrives at the customer site later this year, it will bring the installed base of MetalFAB1 systems to 10 with more possible in 2020. This customer was able to consolidate approximately 700 kilograms of powder in the month of June with the 4 laser MetalFAB1 systems currently in operation. The application represents an inflection point in metal powder bed fusion part production where candidate parts were typically limited to fist size volumes to meet ROI calculations. With the MetalFAB1 systems this customer is able to cost effectively produce over 420 [mm] diameter by 400 [mm] tall parts weighing a whopping 180 kilograms. Please read our press release and see different visuals of the MetalFAB1 system on our Press Page.

Next to the MetalFAB1, Shane Collins, General Manager for Additive Industries North America, Inc.

Next to the MetalFAB1, Shane Collins, General Manager for Additive Industries North America, Inc.